IOT

Solving the Product Variation versus Cost Conundrum

In 1909 Henry Ford famously said about the color of the iconic Ford Model-T car – “You can have any color so long as it is black”. Why did Ford say this? In the years between 1914 to 1925, Ford build only one model and in one color. Ford’s vision was to build a product that had the simplest and the most reliable design using interchangeable and standard parts, and a product so cheap that almost everyone could afford it.

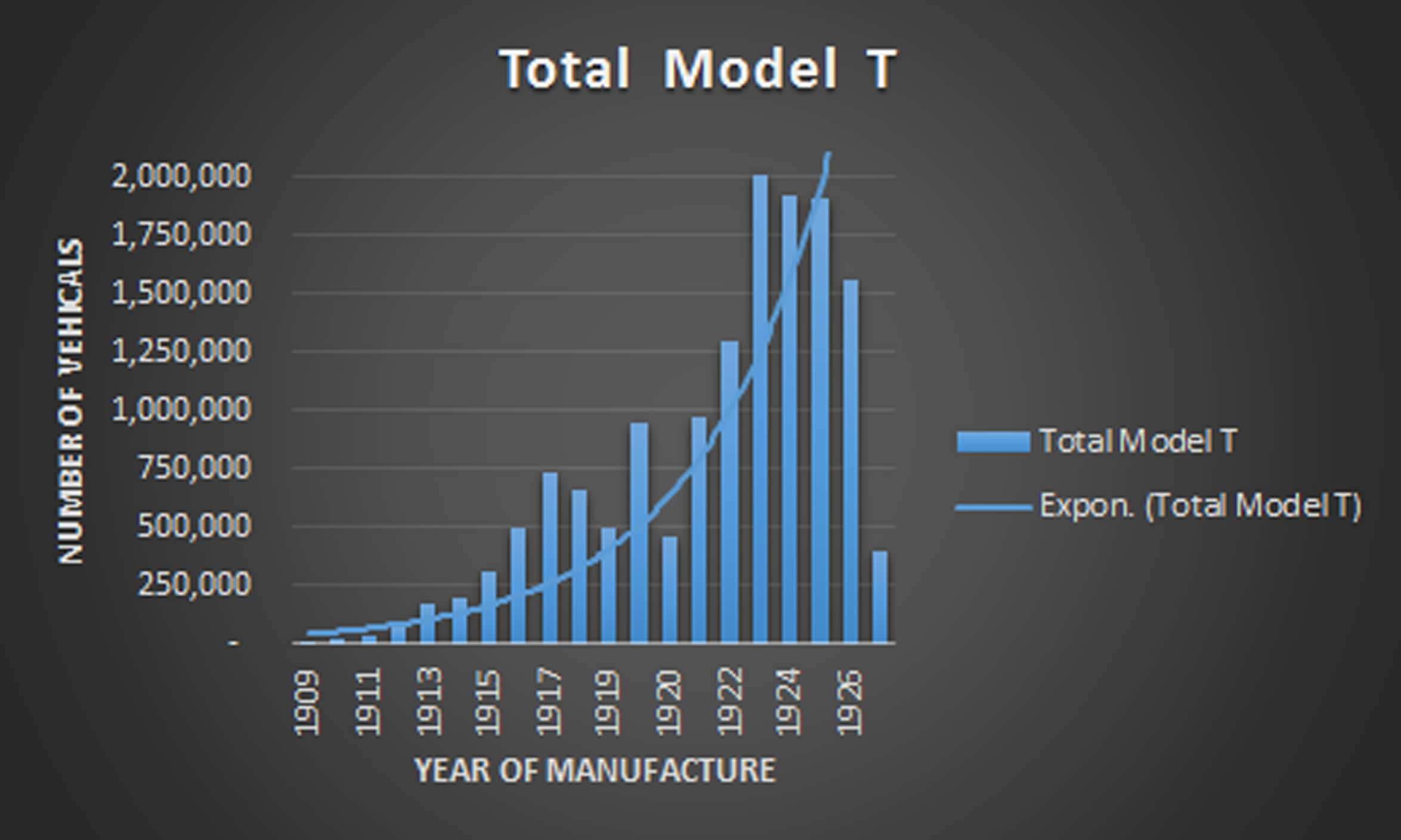

The production data below 1 clearly animates Ford’s vision revealing his plans to scale production which he achieved by 2:

- Building just one model

- Using easy-to-assemble, interchangeable, standard parts

- Inventing the moving assembly line with no variants thus producing thousands of cars every week

- Reducing production time for each car. Minimizing the number of body colors was one way of doing this.

Ford Motors Production from 1909 to 1926

Henry Ford was compelled to stop building the Model T and had to bring back more colors because his customers wanted more than just a sturdy, affordable car. They wanted style, speed and luxury too. As a more discerning demand placed a burden on Ford to differentiate, the Model T era came to an end.

The Ford story demonstrates that customers are more willing to pay for products that match their unique needs. Even at a higher price. Thus product variety lends a competitive edge to companies that are able to offer tailored products and more choices to their customers. Clearly product differentiation, read innovation, is the key to winning in the market.

But then Every Innovation Comes at a Cost

While product innovation or variety might allow a company to improve its competitive reach, such a change leads to a number of challenges. Challenges with regard to complexity; of products, and of internal processes involving product development, manufacturing, logistics, sales, and after-market services. An increase in complexity leads to higher direct manufacturing costs, manufacturing overhead, quality errors, inventory levels, and delivery times.

Arriving at the coupling point, where the demand lead time matches the supply lead time (the point where you do all your inventory and production planning), gets complicated when you try to bring product differentiation. The more choices you offer to your customers, the more complexity it adds to your production and sales processes. Therefore, for every custom order that you accept from your customers, standard processes on the supply side get disrupted, throwing your entire engineering, production and sales cycle off balance.

Enterprises use different systems and tools to manage the various processes that fall under engineering, manufacturing and sales. PLM Systems manage the design and engineering of products; ERP Systems manage planning related lifecycles like order inventory. Product configurators are primarily used as sales tools, to create quotations for a product that the customer requests. But are these systems talking to each other? Do they ensure that what the customer ordered is precisely what the engineer designs and the production team produces? Is your sales tool quoting the right price but not passing on the product specifications to the engineering department?

How then do we solve the conundrum of the need to “innovate” and “differentiate” while simultaneously needing to control increasing “complexity” and concomitant “costs”?

Creating a Digital thread

For successful execution of a customer order, it is essential to do two things – digitize the interactions between sales, engineering, manufacturing, and logistics applications and create a governing body that can arbitrate the rules of these interactions. I would call it an Integration of Things, (a different take on IoT!) where we create a digital thread to assimilate all the relevant activities and position the Product Configurator, which hitherto was not integrated into the value chain, as the key arbitrator on the rules of these interaction.

Significant benefits of weaving a digital thread are:

- Reduced lead time for delivery of products due to more correct and timely specifications and increased material planning reliability

- Increase in on-time delivery due to error free and timely specifications

- Reduction in production cost due to more standardized configurations and error free specifications

- Reduction of engineering costs due to single source of truth via the Configuration and PLM systems

- Formalization of engineering knowledge

- Increased sales

Using a simile of a thread holding together a well woven dress, a digital thread plays an instrumental role in holding the seam of an organization and its processes. Join me at Liveworx at BCEC, Breakout Six on June 19, where I will tell you the complete story of the digital thread.

1http://www.mtfca.com/encyclo/fdprod.htm

2https://www.history.com/this-day-in-history/ford-motor-company-unveils-the-model-t