Industry Stories

Performance, Schedule, Cost Conundrum in Large Commercial Aircraft Design

Like most industries, the large commercial aircraft industry has undergone major transformations in the last hundred years that it has been around. But the past 35 years have been significant, throwing up many tough challenges for players in the industry. Consider these: A significant player in the past, Lockheed, is nowhere to be found today in this market. An upstart conglomerate, Airbus, came from nowhere in the late 1970s and has today become a primary air transport manufacturer. Boeing, meanwhile, absorbed its former chief competitor, McDonnell Douglas, in a merger in 1997. More recently, challengers from Brazil, Canada, Japan, China, and Russia are gaining traction in the smaller single-aisle-airplane marketplace. These examples raise an important question – what issues have caused these radical changes?

The list is long. The US deregulation in the late 1970s caused severe price competition. Access to slots (gate positions) at airports became limited and as global economic cycles waxed and waned, travel did the same since it is strongly tied to the Gross Domestic Product (GDP). Travel was also intensely affected regionally by the events of 9/11 and Severe Acute Respiratory Syndrome (SARS). Even though those were one-time events, they had a long-lasting effect on travel. The price of fuel has also been a significant challenge for aircraft designers. The cost of fuel skyrocketed as a barrel of oil went from US$10 to US$50, and later US$140, now back to US$30. The volatility in oil prices makes it difficult to set fuel burn requirements for an airplane five years in the future. Recently, the strengthening of the Dollar against the Euro has become important as well, since most airplane contracts are in US dollars. In contrast, most labor and material costs are in the local currency where products and parts are built.

Bigger concerns: New technology and long design cycle time

While all these challenges are daunting, I consider long design cycle time and the propensity for new technology to have more greatly hindered the ability to quickly and reliably bring to market next-generation commercial airplanes.

Many are familiar with the stories and legends of the 1930s and 1940s according to which airplanes were designed, built, and flown in a matter of two years. For instance, the B-26 went from a paper concept to being operational in two years. Martin submitted its design in July 1939, flew the airplane in November 1940, and began deliveries to the US Army Air Corps in February 1941, eventually producing over 5,000 B-26 bombers. The B-17 Flying Fortress had a similar timeline, progressing from specification to prototype fly-off in a single year.

War time focus, energy, and requirements are not the same as for a 20-year commercial airliner. It would be facetious to claim that such a timeline could work today in commercial aircraft. However, the duration to design, certify, and put an airplane into service has steadily grown. According to Aviation Week Intelligence Network, the DC-9 had only 205 days between first flight and delivery. The 777 first flew in June 1994and was delivered in June 1995. Many of the most recently developed airplanes have taken over 550 days between their first flight and delivery to an airline. The Concorde had more than 2,400 days between its first flight and first delivery. It is likely that the new technology needed to fly faster than the speed of sound in a commercial airplane, caused the long development time.

The performance, schedule, and cost conundrum

The driving requirements today are much different. Air travel is becoming a commodity as are the airplanes that carry us. Passengers care about safety, while getting from point A to point B, and most choose flights by price. The airlines want as many seats as is practical with the appropriate range to travel between the most desired city pairs.

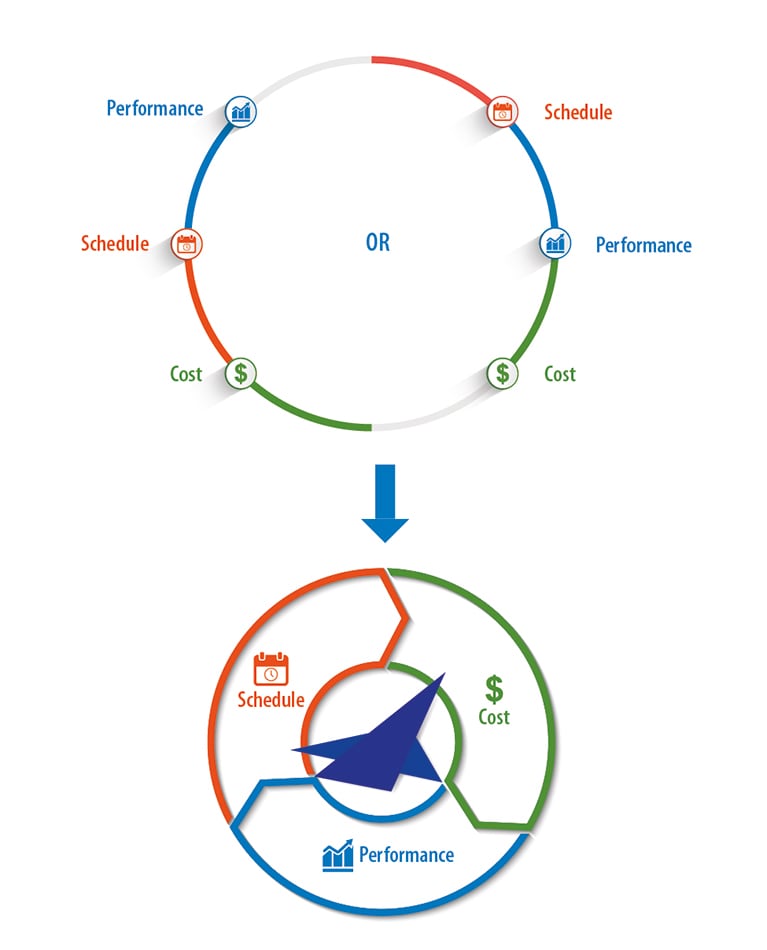

Why don’t airplane builders work on the cost of their products early in a program? Early in my career, I had a chief designer who had three cards pinned to his office wall. He arranged them in top to bottom order in terms of current importance. At the beginning of a program, the cards read performance, schedule, and cost in that order. Sometimes during the program, they would switch order, but cost was always last. Cost consideration must be a priority but it should not become the compromise point for designers.

The most important early decisions are around getting the airplane ‘correct’ for its market segment. Performance rules early on. How many seats? How much range? What is the weight? What are the aerodynamics and controls needed to make all these synchronize around a design? Secondly, the schedule becomes a key. The many gargantuan tasks include engineering, planning, build, system design and testing, ground and flight testing, and certification. Generally, the engine manufacturer will be running a parallel track program to certify the engine one year before the airplane so it will be ready for its first flight.

Much money is invested at this stage of the program. Nonrecurring costs such as engineering, tooling, factory buildings, and equipment are committed and plans implemented. Large bets are made on which technology can be ready in time for production and how much it will save in recurring cost when production is at maximum rates. Other recurring costs include direct hand labor, support labor, purchased parts, overheads, and depreciation.

In Dr. Leland M. Nicolai’s book, Fundamentals of Aircraft Design (1975), he points out two critical items:

- The majority of the aircraft life cycle costs (around 90 percent) are cemented in the first two years of design

- The selection of new technologies that are not mature can cause costs to skyrocket Dr. Nicolai closes with a note about the “painful compromise a designer must make between performance and cost.”

The feasibility and viability imperative

The solution appears to be self-evident: Do the business case for new features and technology and do not include a feature or a new technology just because it is the ‘next big thing.’ Ensure that what is desirable is not only feasible from an engineering perspective but also viable economically. Determine the target cost and ensure that the target cost is met on each of the subsystems of the product.

Seems easy enough. Some industries, indeed, tend to do this better than others. Automobile manufacturers have target costs allocated down to the subsystem level. A designer keeps working until the design meets all three requirements. The margin for cars is much smaller. Imagine being US$300 high on a US$15,000 car. If a model price point is missed, that car will be a failure.

Even within the commercial aircraft industry, engineers encounter such dichotomies every day in solving problems of functionality versus manufacturability, or strength versus weight, and they succeed in designing and building a marketable product. Why then, in such an acutely cost-conscious market, do we still have aircraft programs that result in products that cost more than what the customers are willing to pay?

Almost every large aircraft program is plagued with the high production cost problem. Predictably, product launches are followed by months, and sometimes years, of effort to optimize the cost by modifying the designs, manufacturing process, or the supply chain until the product becomes viable. So much so that engineers have accepted this as the norm. They make decisions by prioritizing performance and schedules and are resigned to the fact that they will address the `cost issue’ when they get to the `cost reduction phase’ of the program. While this prevalent practice often helps meet the cost targets eventually, it is a highly suboptimal process with a lot of cost reduction opportunities left on the table.

The post facto design space is rather severely constrained for the engineer. Most of the designs are frozen and render themselves ‘untouchable’ due to high collateral impacts. The supplier base is identified and contracts are frozen, and significant investments are made in manufacturing tools and fixtures. For every cost savings opportunity identified, you can’t implement three others because you no longer have the business case to make the changes.

After every such cycle, for everyone concerned, it is always – “give us one more chance and we won’t mess up this time.” But the cycle seems to repeat itself despite everyone’s best efforts.

In trying to architect a solution for this problem, I kept going back to the three cards of performance, schedule, and cost. How do I stack these cards so that my engineers don’t have to choose one over the other, but rather achieve all the three objectives simultaneously? How does one go about changing the DNA of the organization to concede equal priority to cost?

In answering these questions, we looked at the existing models of concurrent engineering and development within the aircraft industry. For example, most improved cost design ideas tend to increase weight. But over the years, the industry has built a strong process and a working model to set weight targets, monitor weights with each step of the design evolution, and consistently achieve such aggressive weight targets. Similar challenges exist when it comes to designing for strength, produce-ability, and sustainability. Each day, these challenges are overcome through communication, feedback, and exchange of ideas within an integrated function team construct. The solution is to base the design-to-cost working model on the same lines of the integrated functional teams:

- Provide equal standing for the cost engineer as other functional groups

- Strengthen his / her role by enabling signature authority for the cost engineer

- Enable the design engineering community on design-to-cost best practices and empower them with the right tools and training

- Make some considerable investments in this area and augment that with consistent messaging from the leadership team

Commercial aviation has not only endured, but flourished in the past 100 years, despite challenges. Design-to-cost is just another hurdle that can be conquered with an integrated, prioritized approach.