Digital Supply Chain

Supply chains have traditionally focused on efficiency and cost optimization. But now, flexibility and agility are vital to staying relevant amid rising disruptions and uncertainties. Digitization is key for an efficient and transparent supply chain that enhances responsiveness through agility. A self-curating supply chain alerts on critical issues and recommends appropriate actions. And then, organizations sense, react, and act competently to become future-ready with predictive capabilities.

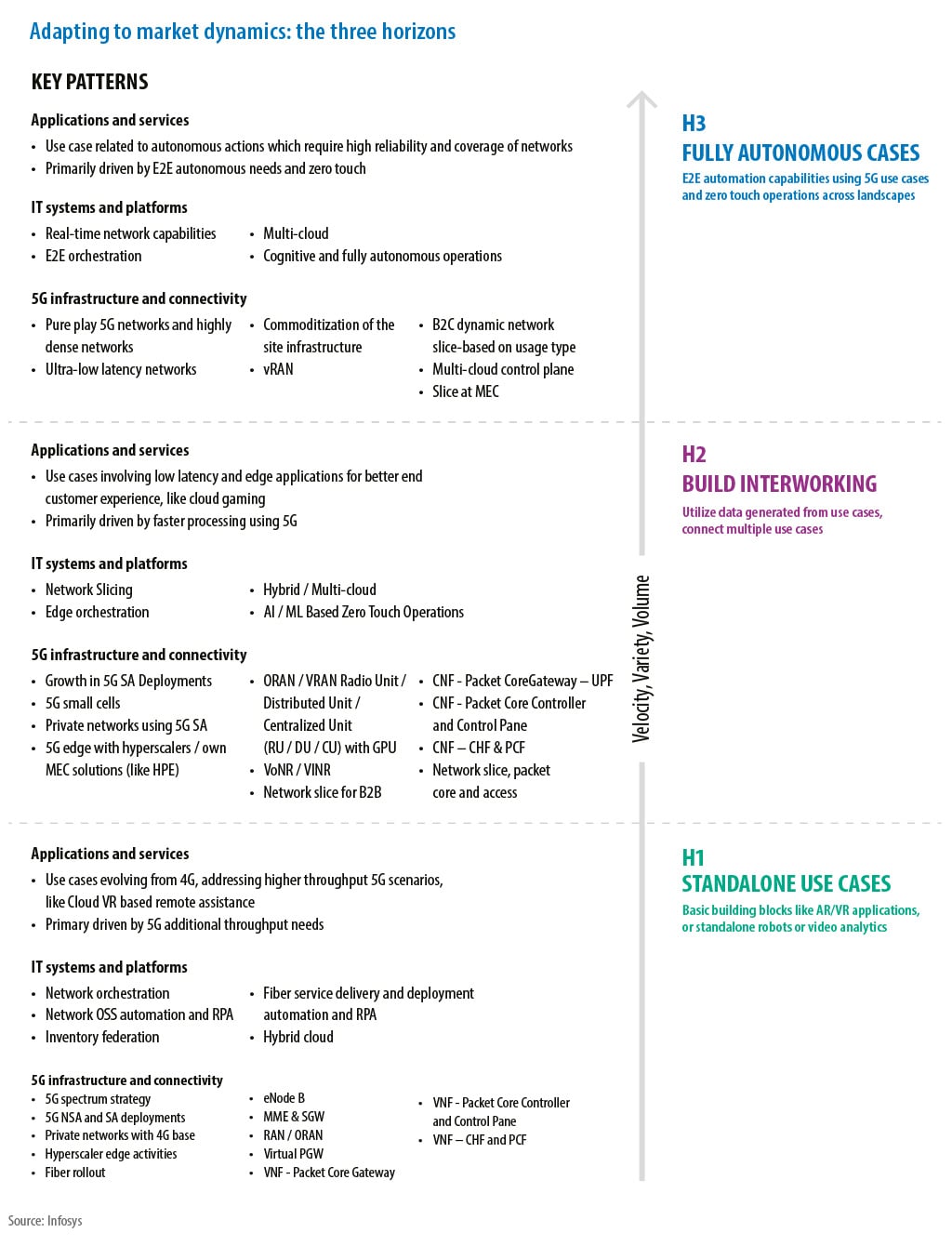

H3

Self-curating supply chain

Supply chain capable of learning and evolving with minimum human intervention

Key Patterns

- Virtual monitoring and autonomous control

- Prescriptive capabilities

- Cognitive automation

- 5G

- Supply chain as a service

- Green supply chain

H2

Intelligent supply chains

Predictive insights for users to take business decisions

H1

Supply chain visibility

Real-time monitoring of key supply chain elements, including KPIs

Key trends across digital supply chain subdomains

Trend 1

Make-to-order with consolidated procurement to navigate supply shortages

Global challenges that started from the pandemic to supply chain disruptions, such as the Suez Canal blockage and the more recent Ukraine war, have resulted in a severe shortage of critical parts and materials. One trend prevalent in discrete manufacturing to address this challenge is the shift to make-to-order business models.

Trend 2

Increased data sharing for supply chain transparency

One approach to mitigate the risks associated with supply chain disruptions is transparency. A digital supply chain uses technologies to measure key parameters and share them with a central control tower. Another approach is that stakeholders not only gather relevant information, but also share it with partners.

Trend 3

In-factory and supply chain operations reach end-to-end digitization

Industry players strive to create a digitally integrated system that collects data on all objects and processes within the factory and on external supply chain elements. Such end-to-end digitization of materials, machines, and processes enable faster changeovers, single-minute exchange of dies, and plug-andproduce capabilities, resulting in improved yields.

Trend 4

AI-based predictive maintenance and smart automation

AI-based predictive maintenance solutions prevent equipment/machine shutdowns and efficiency losses by proactively attending to maintenance issues and ensuring the timely availability of spare parts. Data collected from various equipment/machines in real time is used to detect patterns and improve maintenance schedules, which leads to better firsttime fix rate.

Trend 5

Stockless order fulfillment becomes the norm

Typically, retailers sell the stock they have. But, given the turbulent times, many retailers often don't have that stock on hand. Stockless order fulfillment enables brands to network with retailers and distributors to share inventory data. If the stock is unavailable at the brand's warehouse, orders can be fulfilled from the partner retailer's warehouse.

Trend 6

AI-powered demand planning gains prominence

Uneven demand in highly fluctuating environments is a major challenge for companies, especially for multiple products across geographies. Demand forecasting errors can lead to excess stock or out-ofstock situations. Regional factors such as weather, sports events, and cultural differences add to the complexities. Several parameters in a complex supply chain make it difficult to manage decisions and demand.

Trend 7

Digital twins adoption grows for existing and new mine sites

Digital twins help miners improve mine performance for existing and new mine sites. These virtual models of physical sites create a virtual replica of physical mine site objects. The systems rely on technologies like AR/ VR to model and simulate mine site and activities, which is in turn used for cause-and-effect analysis to better predict and solve operational challenges.

Trend 8

Miners turn to smart inventory management and logistics to optimize supply-chain

Capabilities like inventory management and logistics are essential for asset-intensive industries such as metals and mining. The same has sustainability imperatives in addition to the core operational performance. To optimize inventory and logistics, a company needs to deal with several variables.

Download Insights

What's New

Latest White Papers, Tech Blogs and View Points

Ask Experts

Subscribe

To keep yourself updated on the latest technology and industry trends subscribe to the Infosys Knowledge Institute's publications

Count me in!