High-tech is a fiercely competitive, fast-moving industry, with short product life cycles and increasing price sensitivity as markets mature. How can firms ensure that their business processes keep up?

This paper explores Robotic Process Automation (RPA) as a means to make faster, better decisions. Decision making speed is essential for supply chains, those complex physical and virtual networks that operate twenty-four hours a day, in global synchronization.

Technology has become ubiquitous, with electronics and software emerging as an integral part of all types of products. High-tech industry in this report, refers to semiconductor manufacturers, component makers, distributors, OEMs, value added resellers, and service providers who implement and embed the software to deploy the product for end users.

Supply chains thrive on quick decision-making

Why is decision-making speed important? Because in high-tech, time matters. For example, a personal computer loses 30 percent of its value, only 10 percent into its life. This pressure is felt across the value chain, rippling back from the OEMs like a bullwhip through the supplier network. High-tech has been an innovation-driven market with short time-to-market and constant margin pressure. End products tend to have many variants due to their modular nature and are configured to order with personalization, as close to the consumer as possible.

Why are high-tech supply chains so difficult to manage? The modular nature of these products requires maintaining a large number of components. Televisions, as an example, have 1,200 components, increasing the complexity to manage stock keeping units (SKUs) in a dynamic, demanding, and shrinking life-cycle environment. High-tech enterprises determine manufacturing locations through a continually evolving algorithm of labor cost, skills availability, demand centers, and logistical networks. Geographic decisions are far from static, with risks across multiple dimensions.

Given this combination of factors, order fulfillment and customer service are significant challenges in the high tech industry. Supply chains must be capable of meeting order fill rates while ensuring overall costs are under control.

Slow decision-making hinders business growth

Decision delays on price points, inventory levels, and order quantities have a direct impact on revenue, margin, cash flow, and customer satisfaction. Wrong decisions and even slight order delays generate significant problems in customer satisfaction and business metrics. The deterministic nature of the problem makes it an ideal candidate for automated, rational decisions, using pre defined conditions and rule based exception handling.

How does RPA help?

Robotic process automation (RPA) is the use of specialized computer programs known as software robots (bots), to standardize and automate repeatable business processes and mundane tasks with rule-based software. As a virtual assistant, bots complete tedious and programmable tasks faster, freeing up time for employees to concentrate on more interesting, value-adding work. RPA utilizes an existing user interface (UI) and can run on any software or platform, including web based applications, ERP systems, and mainframes.

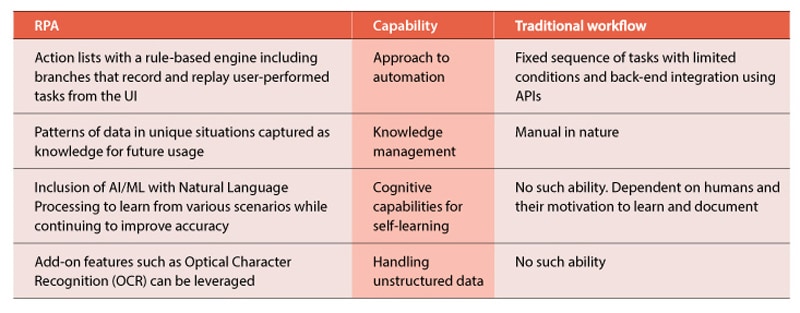

RPA helps organizations make faster decisions by automating tasks delayed due to excessive process time to organize and present data. In the traditional method of automating workflows, a programmer produces a sequence of actions to perform a task and integrates or connects to the back-end system such as an ERP or CRM, using application programming interfaces (API) and scripting languages. However, RPA implementations generate action lists by recording user-performed tasks in the application UI. Those recorded tasks are then performed directly and repeatedly on the UI, in an automated manner.

The power of RPA is that historical patterns of data in unique situations can be identified and captured as knowledge used for future decision making. In supply chain management, this automated and rapid decision-making can be leveraged to manage commonly occurring scenarios such as order fulfillment, delay escalations, customer interactions, and change management.

Change management in order fulfillment involves updates to order attributes, and not all of them are straightforward – quantity, destination, time and mode of delivery, and alternate parts due to unavailability or obsolescence.

AI-powered solution

When enterprises introduce advanced technologies like artificial intelligence (AI) and natural language processing for cognitive capabilities, more complex tasks such as vendor selection and supply-demand matching can also be automated. These RPA capabilities, in combination with AI, have led to widespread adoption in the supply chain to replicate – and accelerate – what humans have traditionally done: capture, process and share data, and make judgments capturing knowledge from past actions to aid future decisions.

Fig. 1 shows the core benefits of RPA adoption. RPA interacts with existing IT architecture without requiring complex system integrations or changes to existing systems and processes. It does not require application code development, nor does it need direct access to an application or its database. Any organization using human effort on a large scale for high-volume transactions and processes can improve its capability, quality, and productivity through RPA.

Figure 1. RPA benefits

RPA mimics and streamlines repetitive business processes. Further, AI algorithms manage business tasks that involve analysis and complex decision-making. RPA, when combined with AI, is even more powerful and achieves better results. With the addition of AI, bots add value to systems rather than duplicate tasks which humans were doing previously. AI adds a brain to the system, where RPA acts as the arms and legs of process execution.

Success stories

In a recent client example, a global logistics firm needed to process orders faster, for better customer experience, and to scale up their operations. A team of 1,000 customer service agents handled booking requests from order creation to their review and updates, in a time-consuming process.The process was predominantly manual, with multiple systems and external data forms.

RPA implementation together with parallel processing for handling requests and confirming status led to significant cycle time reduction. Backlog also reduced from 55 percent to 16 percent. With reduced cycle time, RPA significantly accelerated the decision-making process as well. As a result, the company made better decisions faster. The cumulative effect of faster decision-making is nonlinear and promotes a culture of rapid decision making and learning.

There are multiple use cases for AI based RPA in high-tech supply chains. Procurement is a frequent use case area, like workflows where commodity price exceeds the threshold set in the rule engine. The bot predicts price by analyzing market data, spots an upward commodity price trend, and then creates a real-time demand forecast for the end product which is also trending upward and decides to overrule the upper threshold to place an order for the commodity.

Another example is an AI-based RPA solution that can recognize the arrival of an invoice, identify supplier performance, and then trigger an action in the accounts payable system to initiate payment – all without human interaction.

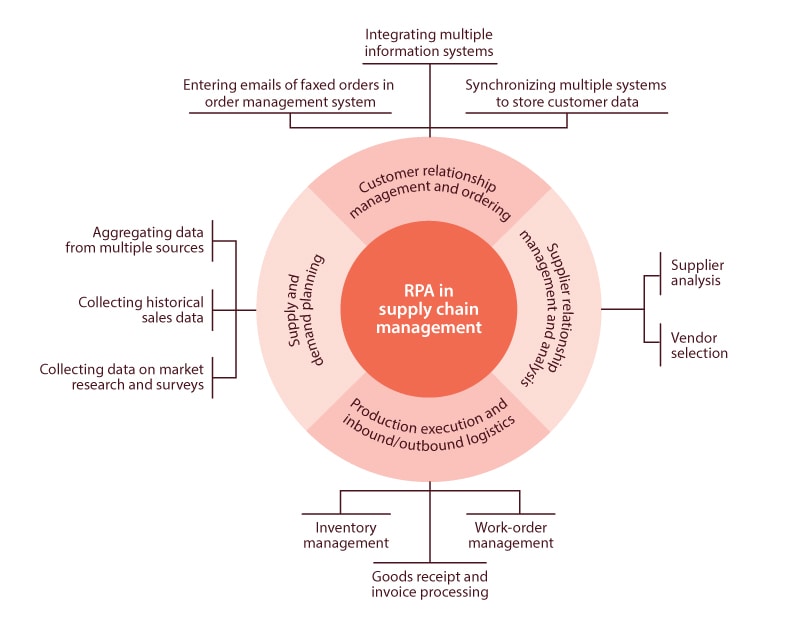

Fig. 2 shows the broad areas of RPA application in supply chain management. These findings indicate more than 40 percent reduction in human effort possible in order to cash processes.

Figure 2. RPA application areas in supply chain management

RPA helps foundational IT processes like Master Data Management (MDM) execute more rapidly in areas like parts and supplier data, lead times, order quantity, safety stock calculations, and purchase order creation.

With inventory management, RPA also improves obsolescence and end-of-life management decisions, avoiding delays while maintaining or increasing accuracy. For example, a low-demand SKU can be returned to a vendor, if identified early enough. The rate to find slow-moving SKUs can be accelerated, also improving inventory turns.

RPA, in concert with underlying operational analytics, helps organizations gain insights and identify inefficiencies. These insights identify bottlenecks and potential disruptions, enabling workflow reengineering to create leaner and more responsive operations.

RPA is not a panacea or universal solution. One caveat is the difficulty for RPA to read non-electronic and unstructured data like manually produced documents. However, enterprises can overcome this by incorporating adjacent technologies that include optical character recognition (OCR) and pattern recognition like machine learning.

Accuracy is vital, as mistakes in implementation can quickly replicate hundreds or even thousands of times before they are detected. Quality assurance with well-designed test plans mitigates such risks. RPA alone does not have self-learning capabilities and therefore has a limited shelf life for a given model. However, with at least periodic improvements, RPA can stay fresh and relevant, and become a dynamic catalyst for change – in some respects, the next generation tool for Lean Six Sigma.

A near-perfect solution?

Enterprises in fast-moving industry segments such as high-tech cannot afford to ignore RPA. Our research has shown that nearly all high tech firms have begun their RPA journey, and many have moved beyond experiments and pilots. However, RPA’s potential for efficiency improvements, combined with its foundation for machine learning and cognitive AI, creates a real sense of urgency to accelerate its adoption. RPA offers benefits beyond just productivity and faster processing of business processes and underlying transactions. Businesses that use machines and algorithms to improve decision-making also enable humans to focus on more innovative and challenging work.

In today’s era of affordable automation, process execution speed must not become the constraint on overall enterprise velocity. RPA alone has its limits, but when integrated with AI, its rule-based efficiency becomes smarter and more predictive. Even in the unpredictable high-tech industry, RPA-aided decision-making provides a better foundation in the never-ending quest to stay competitive.