The digital transformation journey

The manufacturing industry has long sought faster and cheaper production, from the use of assembly lines to industrial robots. But that’s not enough in a world with increasing product complexity, such as connectivity and embedded software.

New competition, customer demands and product challenges are pressuring organizations to move beyond old approaches and embrace Industry 4.0.

The complexity of the manufacturing industry also makes it well suited for digital transformation, where people and machines collaborate more closely. The sector is set to evolve from mass production to mass customization.

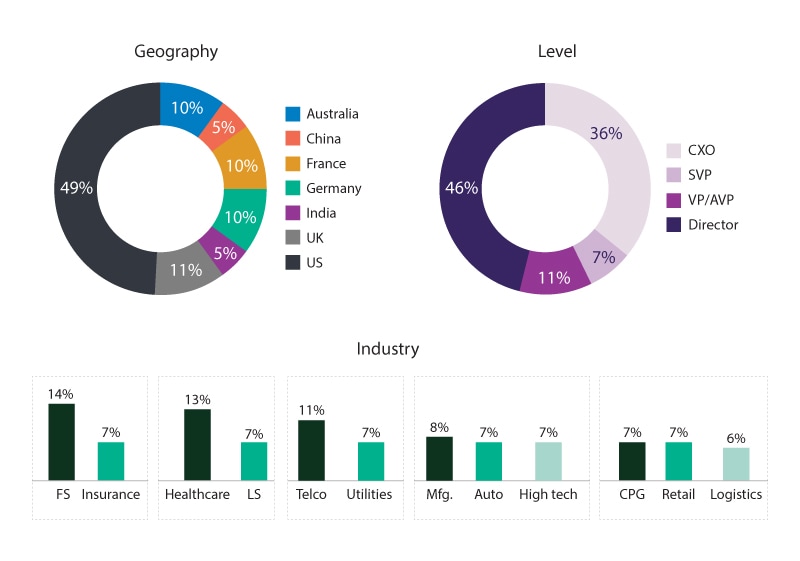

In early 2018, Infosys surveyed more than 1,000 senior management level executives working in large organizations around the world with more than 5,000 employees and over $1 billion in annual revenue. That research on their digital evolution included responses from dozens of manufacturing industry executives.

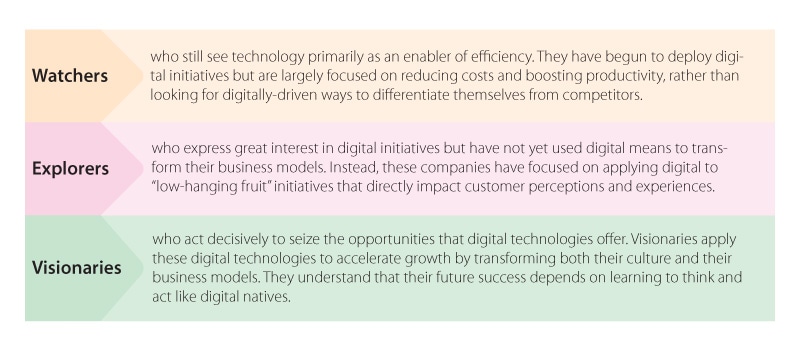

Based on that survey, we produced a report — Infosys Survey Report — showing that incumbent organizations (as opposed to digital natives) fall into three clusters determined by their progress along the digital transformation journey:

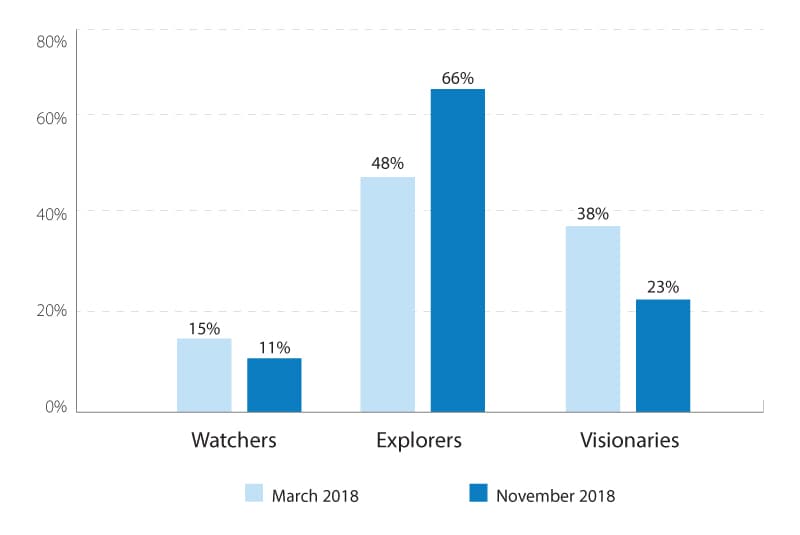

Knowing that many organizations are rapidly intensifying their digital transformation efforts, Infosys conducted a new survey in November 2018 to gauge the pace of that change. This new research shows that the percentage of manufacturing watchers and visionaries decreased, while the number of explorers increased. The decline in visionaries could partially be explained by the different collection of companies surveyed. Overall, executives told us that companies can advance from the watcher to the explorer level without herculean effort, but reaching the visionary level is significantly more difficult.

But advancing in their digital journeys is particularly important now, whether to fend off nimble incumbent competitors or startups taking advantage of lower entry barriers. The rise of additive manufacturing, open source software, knowledge sharing and multi-modal logistics makes it easier to compete against traditional industrial titans.

Fewer watchers, more explorers

The need to be visionaries

Almost every incumbent industrial manufacturer is being pushed by disruptors or peers to digitally transform as 3D printing, smart products, collaborative robots (cobots) and other advances become commonplace. Many companies will only survive if they become digital transformation visionaries.

Some incumbents unable to keep up with the pace of technological change have already succumbed to competitive pressures. Many more in manufacturing will likely fall by the wayside. To avoid being blindsided by competitors and stay relevant, companies must find ways to transform their products, processes and business models using digitally-enabled approaches and technologies.

Navigating the transformation journey

Our most recent study takes a closer look at the transformation journey. We identified 22 key digital initiatives and then asked respondents where their companies stood on implementing each initiative:

- Not started (or in planning).

- Completed multiple proofs of concept.

- Completed pilot projects.

- Operating at scale.

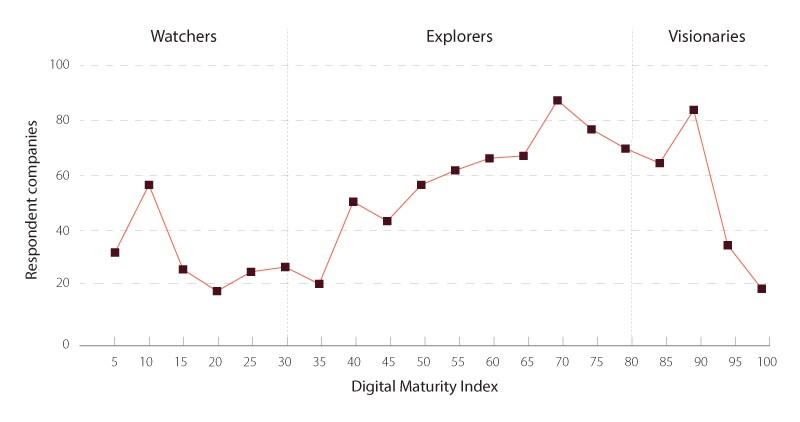

We then developed the Digital Maturity Index and assigned each company an index score from 0 to 100 according to its progress on pursuing and implementing the 22 key initiatives.

Companies on the digital journey

Comparing clusters on their digital transformation journeys

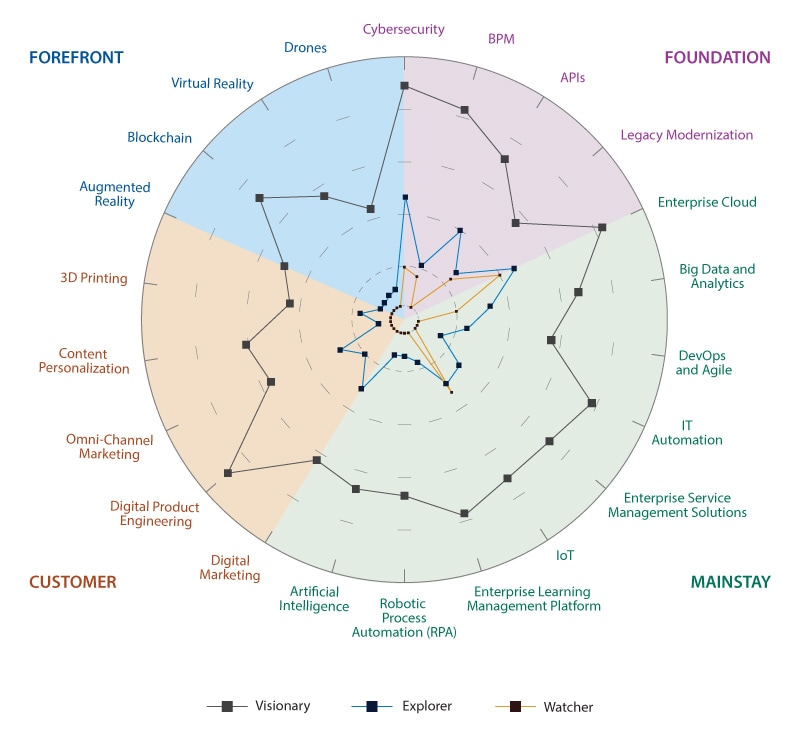

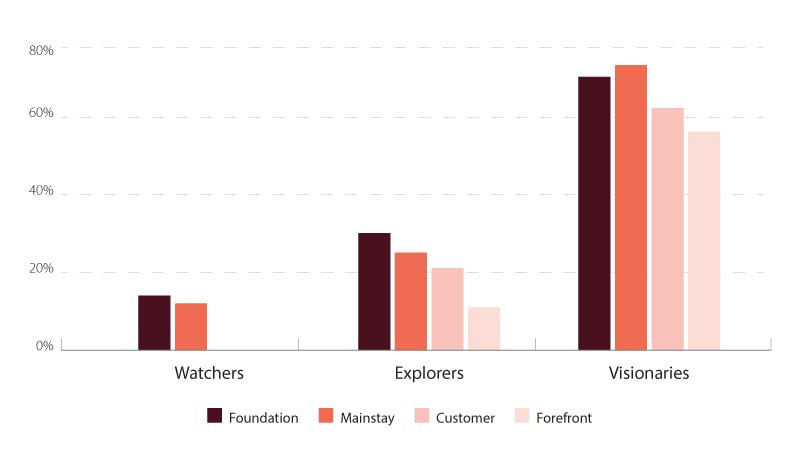

As industrial manufacturers advance through the digital transformation journey from watchers to explorers to visionaries, they operate more and more key digital initiatives at scale. The types of projects change throughout the journey and can be grouped into four categories:

- Foundation initiatives must be implemented to modernize legacy systems.

- Mainstay initiatives represent the core elements of digital transformation, including automation and artificial intelligence (AI).

- Customer initiatives primarily impact the customer experience. They include omnichannel marketing and content personalization.

- Forefront initiatives harness cutting-edge technologies, such as augmented reality (AR), drones and blockchain.

Visionaries stand out – cluster progress across 22 digital initiatives

As shown in the previous figure, visionary manufacturers are significantly more advanced than explorers in their implementation of virtually all initiatives, and watchers are far behind.

Watchers

- These companies typically operate at scale on only one or two digital initiatives, with perhaps a couple of others in the pilot testing phase.

- None of the industrial manufacturers had advanced beyond the planning stages on any of the forefront initiatives. And only a quarter had made that much progress on legacy modernization.

- Among the foundation initiatives, cybersecurity shows the most progress among industrial manufacturers (20% at scale and 20% with completed pilot projects). Compliance and liability pressures are driving companies to invest here, particularly as more machinery becomes network connected to suppliers, dealers and even customers.

- Watchers performed slightly better than explorers on “internet of things,” an increasingly import tool for manufacturers. But that over performance could be explained by the small – and shrinking – number of manufacturing watchers, where the relatively few respondents can tilt the results.

- Watchers are investing in Agile and DevOps, with two-thirds of manufacturers completing proofs of concept or pilot projects. However, our research indicates difficulty in converting these small wins to larger initiative success.

Explorers

- Much further along than watchers, explorers in the industrial manufacturing industry have completed pilot projects for an average of six key digital initiatives.

- These companies have progressed past the planning stage on three-quarters of the initiatives. Yet, they are operating at scale on only about six initiatives.

- Cybersecurity is also showing progress for explorers, as the leading area in foundation initiatives. The U.S. National Center for Manufacturing Sciences found that 39% of cyberattacks in 2016 targeted manufacturing companies. A 2018 Marsh & McLennan Agency Cyber Survey Report found that manufacturers hadn’t improved their cybersecurity and that the industry was a “far easier target” than other sectors.

- Earlier investments in business intelligence have provided a foundation for big data and analytics. Explorers in the industrial manufacturing industry have made more progress here than in other mainstay initiatives.

- Companies have also made more progress on digital marketing than the other customer initiatives. This rules-based, revenue-oriented initiative tends to provide a clear business case in industrial manufacturing.

Visionaries

- Far ahead of their peers, on average these manufacturers are at scale for nine initiatives and have completed pilots on seven further initiatives.

- These manufacturers have either completed pilots or achieved scale on nearly all key initiatives, with exceptions only on forefront projects like virtual reality (VR) and AR (6% each still pursuing).

- The overall consistency of progress across initiatives is remarkable, and shows that a comprehensive approach is required to attain leadership. It also implies possible synergy across initiatives, where success in one area like big data may provide core capabilities for another initiative like internet of things. For manufacturers, industrial internet of things is valuable for predictive maintenance, remote monitoring of machinery and identification of safety concerns. Market intelligence firm IDC predicted that 75% of large manufacturers will update their operations and operating models with internet of things by 2019.

- Even in the forefront category, where progress is understandably less advanced than the others, there is still consistency across initiatives. From our discussions with industry executives and experts, this highlights a “lean forward” mindset that embraces the understanding that today’s advanced technologies will become a vital part of tomorrow’s operating system.

Changing focus, making progress

Visionaries have many more initiatives operating at scale

As industrial manufacturers advance along their digital transformation journey, they tend to focus on different sorts of projects. Watchers are just trying to build a foundation for their digital transformation, so they are unlikely to have the bandwidth to launch mainstay, customer or forefront initiatives.

As companies reach the explorer stage, they turn their attention to a broader range of initiatives including such mainstay ones as big data and analytics, robotic process automation (RPA), and enterprise cloud. They can also spend time working on customer initiatives such as content personalization, digital product engineering and digital marketing. However, explorers must still invest time focusing on the basics, such as scaling the implementation of core foundational initiatives such as legacy modernization, application programming interfaces (APIs) and business process management (BPM).

Industrial manufacturing visionaries bring many initiatives to scale along foundation, mainstay and customer categories. They are also the only cluster making substantial progress on scaling forefront initiatives such as 3D printing and blockchain technologies. 3D printing initially was a valuable tool for manufacturers to quickly create and test prototypes. Now the technology has moved beyond that preliminary stage and is often used to create final products.

Shifting barriers on the digital transformation journey

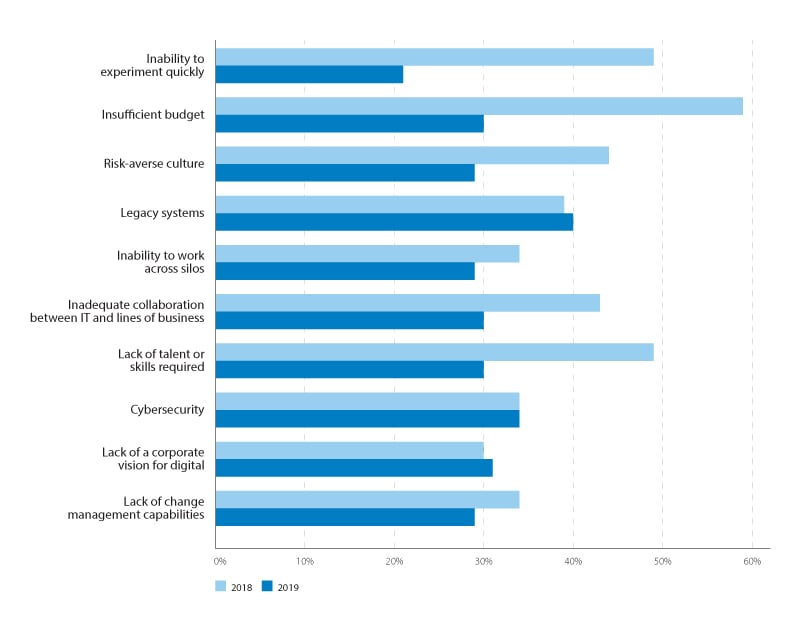

Our survey revealed that an inability to experiment quickly is the greatest barrier to digital transformation that manufacturers faced in 2018. Nearly half of respondents (49%) worry that their companies lack the capacity for rapid experimentation that is essential for testing different technologies and figuring out which ones hold the most promise.

Most companies believe that they can quickly develop this capability. Only 21% of respondents in the manufacturing sector felt that lack of rapid experimentation skills would still frustrate their digital transformation in 2019.

Barriers to digital transformation

We believe that companies underestimate the challenge of mastering the art of rapid experimentation. Companies need to implement major cultural changes to become adept at rapid experimentation, according to Alok Uniyal, vice president and head of Agile and DevOps at Infosys. Significant cultural shifts rarely happen quickly.

While respondents overall feel that most barriers to digital transformation will diminish over time, they have persistent concerns over legacy systems.

Legacy systems currently rank as the sixth most commonly cited barrier (named by 39% of respondents) by manufacturers, and participants expect that it wouldn’t change much in 2019.

Digital natives often cite their lack of legacy systems as a major competitive advantage. Many incumbent manufacturers must deal with the dual problems of antiquated legacy IT systems as well as outdated production equipment. Cloud computing allows organizations to quickly scale their digital transformations. However, manufacturing equipment can prove more difficult since it often wasn’t designed with sensors and other connectivity in mind.

Experience with digital transformation is a double-edged sword. On the one hand, the visionaries who have progressed the furthest along the digital transformation journey recognize the most barriers, identifying four from the list of 10 that we provided.

At the same time, manufacturing visionaries are also more optimistic than their counterparts in the watcher and explorer groups about overcoming these barriers. This demonstrates that companies become more confident as they gain experience with implementing successful pilots and bringing ideas to scale on their digital transformation journey.

Survey respondents are also confident that budgetary constraints will become less of a barrier in 2019. While 59% of manufacturing executives cite “insufficient budget” as a barrier to digital transformation in 2018, only 30% feel that it will still be a serious stumbling block this year. If organizations devote more investment to key digital initiatives, that would show that senior leaders are strengthening their commitment to digital transformation.

Participants also expect that change management will improve slightly as time goes on. While 34% of respondents named “lack of change management capabilities” as a barrier in 2018, 29% said it would be a problem in 2019 for industrial manufacturers. In other industries, concerns about managing change are much greater.

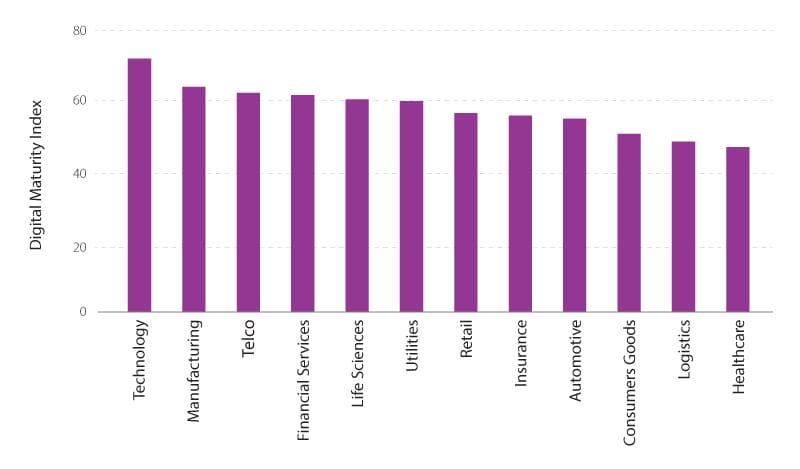

Digital maturity by industry

Our survey revealed significant differences in digital maturity by industry. We found that technology, manufacturing, telco and financial services companies had progressed furthest on their digital transformation journeys. Digital Maturity Index scores were distinctly lower in other industries such as consumer goods, logistics and health care.

Many legacy incumbents are still trying to make progress toward digital transformation, but their efforts are hampered by regulations, security concerns and complex internal processes.

Industry ranking on the Digital Maturity Index

Accelerating the digital transformation journey: 5 key capabilities

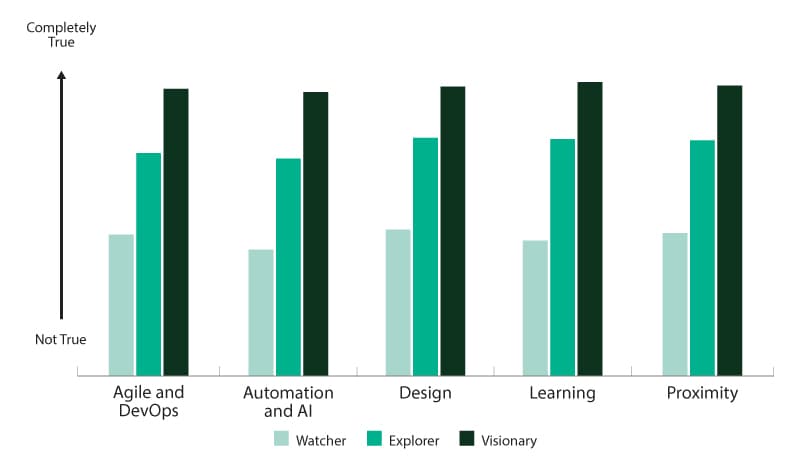

In August 2018, Infosys conducted a research study that identified five capabilities that help industrial manufacturers accelerate their digital transformation journeys: Agile and DevOps, automation and AI, design, learning, and proximity.

In our November 2018 executive survey, we looked deeper to understand company competencies in these areas. We found that companies with the highest Digital Maturity Index scores (i.e., the visionaries) do indeed have the strongest abilities in all accelerator categories.

Visionary companies have superior accelerator capabilities

Cluster average

The five digital capability accelerators above are each powerful in their own right, and we examine each of them on the pages that follow. Before looking at the accelerators individually, it is worth reviewing them holistically at a summary level. When we reviewed client and industry digital transformation programs, we found multiple successes in the past two years where one of the accelerators was dominant. However, in discussions with executives about the next 12 months and beyond, the consistent message was that multiple accelerators will increasingly be needed for future success. Agile and DevOps programs will be required for the uncertainty that accompanies the frenetic ongoing pace of change. The amplification and intelligence from automation and AI will be required to make sense of an increasingly complex world.

Design will become a non-negotiable expectation that goes beyond functionality to experience, and will permeate more and more business functions.

The rate of change faced by enterprises, and the necessity for widespread adoption, virtually guarantee that learning will be a core part of any lasting transformation. Finally, the location or proximity to work will be a major factor in capability and program planning, both for strategic intent and cost management.

Let’s examine each of these digital capability accelerators.

Digital transformation accelerator No. 1: Agile and DevOps

“There’s an overarching need for companies to be nimble and responsive, to understand company needs, and quickly develop solutions,” said Uniyal, Agile leader at Infosys.

“Agile and DevOps enable companies to beat competitors by quickly experimenting, validating ideas and scaling leading-edge solutions. They enable greater flexibility and higher productivity. DevOps helps by automating the Agile software development lifecycle, enabling companies to deploy new features on a nearly continuous basis.”

The visionary manufacturers that are furthest along the digital transformation journey have the strongest ability to deliver Agile programs at scale. They have fully adopted both an Agile mindset and Agile practices. Their IT developers and operations teams cooperate closely to achieve business objectives.

That tech industry approach will be needed as manufacturing equipment is networked to computer systems that were traditionally isolated from factory floors.

Their technology teams deliver results fast enough for these legacy companies to stay competitive and fend off digital native rivals. Such visionaries are also likely to have a robust, stable DevOps platform that serves their entire enterprise.

There are two primary barriers that prevent manufacturers from making more progress on Agile and DevOps.

One major organizational challenge is changing the culture to ensure that business cooperates with IT from the start.

Our research has found that about 80% of development projects are IT-led and IT-sponsored, without early involvement of business stakeholders.

If companies can change their culture and mindset to ensure early business and IT collaboration, they will dramatically improve likelihood for Agile and DevOps success.

In addition to cultural change, manufacturers also need to make sure that their employees are trained in new ways of working. This retraining must extend throughout the organization so that all stakeholders have a good understanding of these new ways of working.

While our survey shows that many companies are confident — perhaps overconfident — in their ability to master rapid experimentation, the reality is that Agile and DevOps techniques are hard to master. Even companies that purport to have flexible, Agile teams may still rely on the same old structured, rigid waterfall development methods inside those teams.

There are practical steps that companies can take to improve their Agile and DevOps skills. Companies can work faster and scale quicker while meeting the demands of global markets by implementing Agile on a distributed basis.

“Companies need to become more dynamic and nimbler,” Uniyal said. “To react faster to changing markets and come up with improved products and services, companies need to have a culture of rapid experimentation, quick development, prototyping and validation. To accomplish this, they need to be able to visualize their end-to-end value chain. This is a major challenge in legacy organizations where the value chain may be fragmented. The best way to overcome this issue is by implementing Lean.”

Digital transformation accelerator No. 2: automation and AI

AI and automation have the potential to radically transform existing business models and unlock new opportunities in manufacturing.

Unplanned downtime – much of that equipment failure – costs manufacturers $50 billion annually, according to a report from IndustryWeek and Emerson. AI-based predictive maintenance offers a potential solution or at least a weapon against that lost productivity.

What distinguishes visionaries from their peers when it comes to AI and automation? Our survey found that visionaries are more likely to have developed and started to implement well-articulated strategies and initiatives for AI, RPA and IT automation. They also tend to approach automation and AI as ways to amplify human capabilities rather than just reduce headcount and costs. Their employees have the skills to implement automation and AI technologies in ways that advance corporate strategic goals.

That said, industrial manufacturers at all stages of their digital transformation journeys are grappling with the ethical implications and opacity of AI.

“We need a paradigm shift in how we interact with AI and automation,” said John Gikopoulos, global head of AI and Automation at Infosys. “We should apply ethics and control at the personal level, rather than expecting a process, machine, or laws to govern these technologies once they are out in the world.”

Better tools are constantly coming to market that give manufacturers new ways to create AI applications. Companies need to figure out the best ways to harness these tools to develop useful solutions that meet client needs. To get the most benefit from automation and AI, most incumbent companies will need to convince their own workforce about the benefits of these technologies and reskill employees to make sure that people and machines can work seamlessly together to achieve superior results.

Manufacturing workers have long been skeptical about robots as automation eliminated traditional jobs. However, the potential for cobots and humans to work side-by-side offers a hybrid approach to increasing automation.

Digital transformation accelerator No. 3: design

Design as a function is no longer limited to coming up with well performing, efficient products made with cost effective manufacturing methods and materials. A systems thinking approach is increasingly adopted by OEMs to keep the big picture in mind. The carbon footprint of products and processes is important for green manufacturing. Ethics play a key role in several decisions taken in the life cycle of a product, from the choice of suppliers to performance in the field. Organizations are concerned about the sourcing of rare materials and ensuring there were no human rights violations or other illegal practices.

Design skills enable companies to rethink every aspect of their business, from internal operations to external customer service. Industrial manufacturers with superior design skills use technology to find novel solutions to serve human needs.

At Finland’s Kone, one of the world’s largest elevator companies, executives talk about elevator design and experience much like an Apple engineer would talk about the newest iPhone. Kone CEO Henrik Ehrnrooth told Forbes about plans to work with building owners on personalized experiences.

“We haven’t seen anyone invest in such as a determined way to create an experience,” he told Forbes.

Our survey shows that companies with design strengths are better able to seize opportunities to improve both customer and employee experiences. They are more likely to deploy technology in the form of digital product engineering, content personalization and AR.

Manufacturing visionaries understand that design is more than mere user experience. Instead of segregating user design within its own silo, they make sure that more people, in more functions across the company have responsibility to design products and services that maximize user satisfaction.

Design-led manufacturers have effective processes in place to continuously listen to customers. They are committed to testing ideas and iterating to make those ideas better over time. They measure design performance and results with the same rigor that they apply to tracking revenues and costs.

When it comes to pursuing design-led solutions, Infosys design executive Corey Glickman warned against excessive prototyping. He said too many companies spend millions of dollars a year on prototypes and proofs of concept, without ever moving on to implement those pilots at scale. In times of disruptive change, companies must bite the bullet and make big bets. It sometimes takes an industry leader or innovative upstart to establish a new norm. “No one would have a digital twin today if GE hadn’t sunk millions of dollars into developing theirs,” Glickman pointed out.

Systems engineering has emerged as a critical role in the digital age. The best systems designers are diligent scientists with master’s degrees and many years of work experience. This type of talent is in short supply, exacerbating the war for talent. However, the good news is that a systems designer with experience in one area can typically apply his or her knowledge to other domains. “Systems designers understand how large, complex systems behave,” Glickman said.

“As a discipline, systems design is universal enough that someone with experience in financial services can apply their skills and experience to software design or health care.”

On a practical, operational level, our research has confirmed the effectiveness of breaking up large projects into small teams of highly-skilled programmers handling the hardest and most important challenges. These all-star coders are hands-on, working iteratively in physical and virtual whiteboard environments, efficiently pulling from reusable code libraries and writing their own fresh code every day. This approach can reduce development time from three months to as little as three weeks. With this arrangement, companies can deliver more effective programming, solve difficult problems faster, and reduce technical debt that may have accumulated through legacy programming and processes.

Finally, the success of design-led digital transformation depends on the involvement of senior executives. Design is helping to transform major components of enterprise operating models, and success requires buy-in and leadership from the top.

Digital transformation accelerator No. 4: learning

Companies are facing a significant gap between the digital skill sets they need and the talent available, according to Jonquil Hackenberg, partner at Infosys Consulting. “Recent graduates, even in desirable fields like data science and enterprise architecture, lack the experience and expertise to implement at scale,” warned Hackenberg. “Meanwhile, many legacy IT professionals struggle to engage with subject matter experts in a way that translates business needs to modern, scalable technology solutions.”

Visionary manufacturers are more likely than other firms to bridge this talent gap by investing in the digital tools and infrastructure necessary to support a robust, always-on, continuous learning and reskilling program for employees.

At the German industrial firm Siemens, trainees use DAQRI AR glasses to learn gas burner assembly skills. That has significantly reduced the training and assembly time, according to Flex, which manufactures the glasses.

Continuous learning is fundamental to developing the workforce of the future, one that can achieve and sustain digital transformation. Employees must become nimble, responsive and proactive enough to identify and seize the best opportunities made possible by emerging technologies and new business models. Our research findings suggest that such continuous learning programs play an especially important role to help employees develop skills in Agile and DevOps, areas that are as much mindset shifts as technical skills.

Employees realize the critical importance of continuous learning to keep themselves marketable and relevant in a rapidly changing business world. Beyond internal skills development, learning programs have the added benefit of supporting retention. Employees appreciate when companies make investments in their career development.

Many leading industrial manufacturers have built their own internal training, reskilling and upskilling programs.

Our research shows that watchers often overlook the substantial benefits of learning accelerators.

For companies looking to make the move from watcher to explorer, investing in learning is an important early step.

Digital transformation accelerator No. 5: proximity

Organizations cannot match the pace at which technology is developing today. That makes it imperative for them to partner with external entities.

Even though many manufacturers are competing in a global marketplace and have access to a growing suite of collaboration and communication tools, distance still adds complications to any initiative or project. On the other hand, proximity enhances collaboration and can remove physical barriers to success in product and IT development projects.

“Value creation occurs when companies bring teams together end-to-end in proximity,” advised Deverre Lierman, leader of the Infosys Raleigh Technology Hub.

“Companies should deliberately structure their ecosystem and choose their partners with an eye to maximize innovation, speed and responsiveness. The key is to capitalize on the benefits of high-quality, low-cost locations without sacrificing the advantages that proximity brings. Visionaries balance global delivery centers with nearby innovation hubs.”

These hubs may be internal or involve strategic partners.

Boeing is looking at an entire country, Japan, as a hub for its research into electric propulsion airplanes. The U.S. aerospace company has announced collaborations with Mitsubishi Heavy, GS Yuasa, Sinfonia Technology Co., Kyushu University, the National Institute of Advanced Industrial Science and Technology and other high-profile Japanese organizations on the next generation of aircraft.

Our data shows that visionaries are more likely than watchers or explorers to have implemented finely- tuned strategies to locate employees together in geographies that balance cost with proximity to partners and customers.

Still, even visionary manufacturers depend on the contributions and efficiency of distributed development teams. Visionaries supply these teams with effective collaboration tools and implement standards to measure the quality of work these distributed teams deliver. To the extent that visionaries rely on global development centers, they also invest in the infrastructure and systems to minimize the impact of distance.

At the same time, visionaries recognize that there is no substitute for physical proximity and are quite willing to establish well-staffed technology and innovation hubs near important partners or customers. That is why Infosys is establishing six new technology and innovation hubs in the United States and staffing them with 10,000 American employees to serve its customers there. Such proximity is especially valuable when working on initiatives involving customer experience, such as product development, content personalization and AR.

Companies looking to reap maximum benefits from proximity should locate their technology and innovation hubs near end users (i.e., clients) and in places that have intrinsic appeal for the talent that the company wishes to recruit and retain. Locations near top universities are also attractive, since those schools can provide a pipeline of candidates for recruitment and an ecosystem for incubating innovation ideas.

Industrial manufacturers at all stages of digital transformation should strive to create a culture that attracts talent. Our research shows that employees want to work in a collaborative and collegial environment, where they know they can focus on getting results without wasting time fighting turf wars.

Practices and mindset — what sets visionaries apart

Every incumbent manufacturer knows that it needs to make progress on its digital journey, but our recent survey indicates most are not moving fast enough. Traditional manufacturers who follow the tollgate-based processes for new product development will lose in the race for domination.

The software embedded in many products today is a driver to make them more efficient and customer friendly, and adapt new features on an ongoing basis. Product makers need to transition to agile ways of working at all stages of the product life cycle, and even redefine traditional models to advance concepts like servitization and sustainability.

How can they move to the visionary level? What sets visionaries apart from watchers and explorers?

According to our research, visionaries stand out in the way they have fully embraced the mindset and practices of both being agile and doing Agile.

To become more like visionaries, companies should put in place a formal digital transformation strategy, and share that plan with employees, customers and partners alike. They should also develop and implement a comprehensive strategy for using automation and AI to bolster human capabilities, rather than just focusing on cutting costs.

These are not trivial matters. Companies will face real challenges around talent recruitment and reskilling, retooling legacy systems, building the five accelerator capabilities and fighting off lean, hungry digital native disruptors.

Incumbent manufacturers need to do three things, do them all well, and do them simultaneously:

- Establish the technical foundations for digital transformation.

- Build technological capabilities and talent.

- Innovate at the speed of Agile.

There are two ways that companies can give themselves a boost on the digital transformation path.

They can seek to amplify their existing capabilities by focusing on high-value projects with the greatest potential impact, and they can partner with other organizations to gain access to complementary skills and resources.

Amplify

Industrial manufacturers have limited talent resources, so it makes sense to focus systems designers’ efforts on the biggest problems where the solutions they create will have the greatest impact. “You can amplify the impact of designers by assigning them to small teams where they can work together to deliver scalable solutions that can be replicated throughout the organization,” explained Infosys’ Glickman.

“If you have the right systems and process, a small number of talented individuals can have a big impact on a company’s digital transformation journey.”

Manufacturers need to figure out which projects to prioritize and how to push the digital envelope where it will matter most. Visionaries are comfortable with different parts of the organization being at different steps in their digital transformation journeys.

Partner

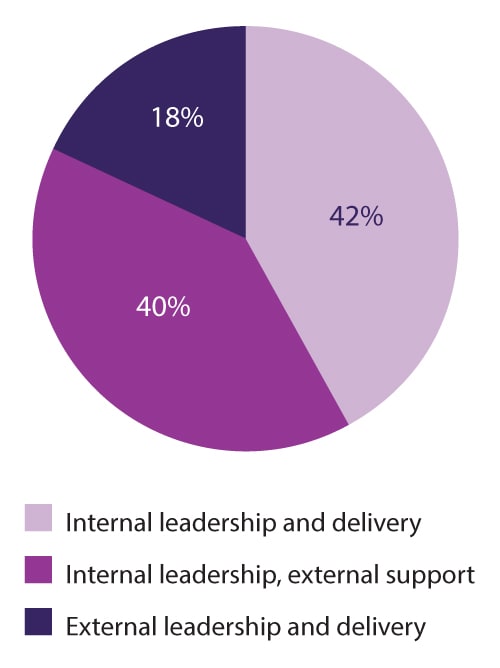

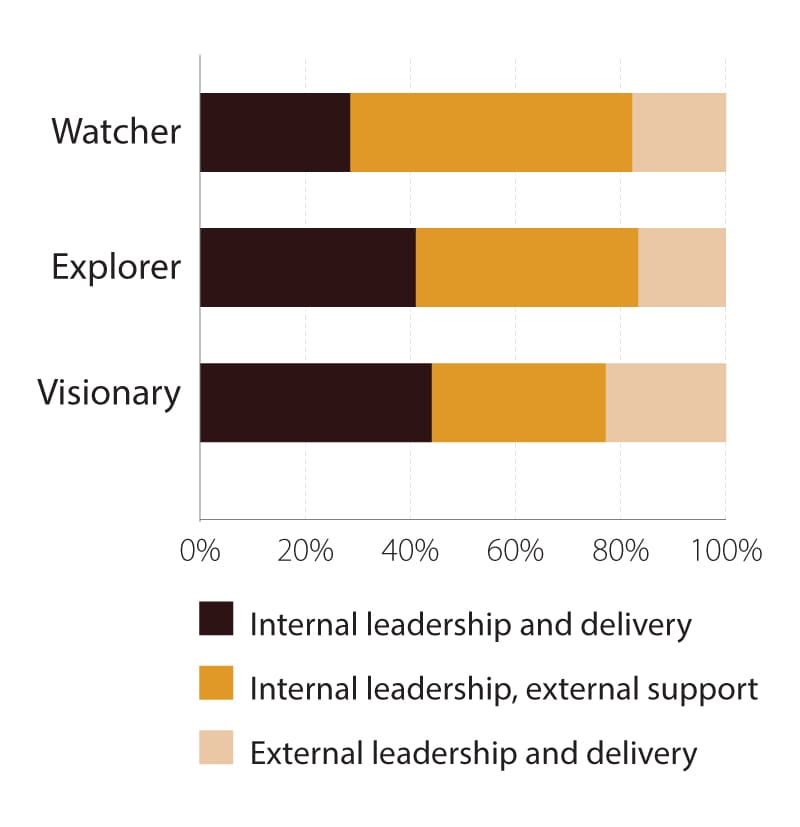

Manufacturing executives told us that more than 40% of digital initiatives are led and delivered internally; about the same amount are led internally and delivered by partners, while the remaining 18% are fully delegated.

Companies partner for more than half of their digital initiatives

There is a significant difference in how clusters handle partnering. Overall, watchers are the most likely to run initiatives entirely internally. Explorers are most likely to lead projects internally, while having them executed externally. Visionaries are more likely than the others to let partners run and deliver initiatives on their behalf. But in manufacturing, this specific group of watchers are more likely to partner.

Watchers are more likely to partner on digital initiatives

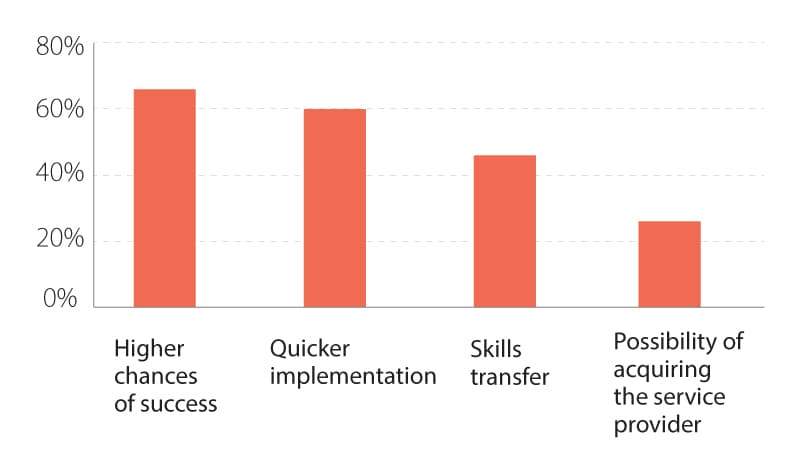

According to our respondents, partnering offers two primary advantages: higher chances of success and quicker implementation.

Partnerships have several advantages

According to our research, visionaries are more likely to form partnerships because they have the process and governance maturity needed to build and run them effectively. It’s the same reason companies that invest in architecture and data management are more likely to support API interfaces with external services. Visionaries also have experience building partnerships and understand the multi-faceted value of a good partnership, so they are more likely to pursue and forge additional partnerships when opportunities arise.

Industrial manufacturing visionaries’ digital accomplishments also give them a better appreciation for the unique capabilities that partners bring to the table. When it comes to the vast world of technology, visionaries who develop certain technical skills also tend to learn that they cannot be experts at everything. Instead, they recognize the value of focusing on their core competencies and gaining access to other expertise through mutually-beneficial partnerships.

Respondents told us the best partnerships are built on strong personal relationships among humans.

Our survey showed that manufacturers are willing to partner on almost any digital transformation initiative, but they are least likely to work with partners on legacy modernization, where they presumably feel they have the in-house knowledge to upgrade those systems on their own.

Survey participants reported that their companies were most likely to ask an external partner to both lead and deliver on sophisticated initiatives like blockchain, AI and AR. At least one-fourth of incumbent companies turn to partners for help with these sorts of initiatives that require specialized, hard-to-recruit expertise.

Industrial manufacturers were more apt to favor internal leadership, while partnering with external help for execution on initiatives such as 3D printing, enterprise cloud and drones. These areas also require specialized expertise and significant resources, but in-house staff may already have some experience in these fields and thus feel more confident directing such projects themselves.

Printing giant HP has created its HP Digital Manufacturing Network to collaborate with other firms on 3D printing solutions, from materials to software.

According to our research, U.S.-based companies tend to view intellectual property (IP) even more as a proprietary advantage than their European and Asian counterparts. As a result, U.S.-based firms more often prefer to develop high-value innovation in-house. European firms partner for IP in a more transactional manner, while Asian companies have shown more openness for partners to take leading roles in IP creation.

Accelerating the journey

As mentioned in the Amplify section above, every industrial manufacturer — including visionaries —needs to prioritize specific digital transformation projects in order to maximize the impact of scarce resources.

How can a company know which projects to prioritize?

- Analyze its level of digital maturity and develop a clear, honest evaluation of current initiatives relative to objectives.

- Assess the short-term future of its industry. What are the key threats from disruptors? Which emerging technologies hold the most promise? How are customer expectations changing? What impact will these factors have on business models?

- Ensure that the company has a solid digital foundation by modernizing legacy systems and working on APIs and BPM. Strength in these areas will enable success in other aspects of a digital transformation plan.

- Strengthen and refine the five accelerator capabilities - Agile and DevOps, automation and AI, design, learning, and proximity.

- Forge relationships with partners whose skills and services could promote faster, better progress toward digital transformation goals.

As with other change initiatives, senior manufacturing executives should take an active role in driving digital transformation initiatives.

Manufacturing leaders have to send a signal that such internal power struggles will not be tolerated. Digital transformation journeys can only succeed when individuals from multiple areas of the organization step outside their comfort zones and work across boundaries for the good of the entire enterprise.

Organizations are still finding new ways that digital tools and strategy can transform their business plans and factory floors, from improving worker safety to optimizing supply chains to enhancing human talent.

The digital future is arriving at a rapid pace, and the consequences for inaction are more severe than ever. With proper planning, cooperation and commitment, business leaders and IT professionals can work together to position their companies for success, no matter which direction the digital winds may blow.

Survey methodology

In November 2018 the Infosys Knowledge Institute used a blind format to conduct an online survey that attracted responses from more than 1,000 CXOs and other senior-level respondents from companies with revenue upward of $1 billion. Respondents represented multiple industries and hailed from Australia, China, France, Germany, India, the U.K. and the U.S.

To gain additional qualitative insights, we also conducted phone interviews with more than a dozen industry practitioners and subject matter experts.

Survey coverage