Reducing product complexity for customers through e-Configure

Product managers play a key role in the Electrification business in ABB, for timely roll out of new products and ongoing upgrades. They oversee the life of a product across the entire supply chain from design through manufacture, pricing to final delivery, installation and service. On top of all this, they need to regularly change the configuration and pricing of products to match customer requests for different applications, or upgrades.

The complication with this process arises from the challenge in collaborating efficiently and seamlessly across ABB’s global network. Different processes, datasets and terminologies used across the locations further add to the complexity. Due to organic business growth and growth through acquisitions, the following challenges to the use of legacy systems and processes arose:

- Duplication of data across different teams with limited common, harmonized database, causing confusion.

- Variation in business processes across business units and locations.

- Usage of conventional tools such as spreadsheets and home grown applications to create product configurations.

These difficulties mean that a typical change in product configuration can take months, causing significant delays in the ability to respond to customer demand. Additionally, the quality of quotes can be poor. For example, an obsolete part that is past its effectivity date in the master system may still be active in a regional system allowing customers to choose them. However, the entire configuration will not be feasible to manufacture. Cost and price information will not be consistent.

To solve these issues, ABB piloted an “e-Configure” solution in order to speed up collaboration across the supply chain, by centralizing data and processes. The aim of the solution was to create a:

- Single source of truth for all products and their associated information.

- Standardized process across teams along the supply chain, and in different geographic locations.

- Collaboration tool for customers and internal teams to co-create solutions.

This was not just a technology implementation, however. The e-Configure tool was central to a complete transformation of the business, away from an “inside-out” approach to one where customers could collaborate and influence the design of products.

This development required a significant focus on cultural change within the organization, not just the technical implementation of the e-Configure solution. The results were very positive. The pilot brought the order-to-delivery cycle time for new products and specific quotes from several months to a few weeks with zero order errors.

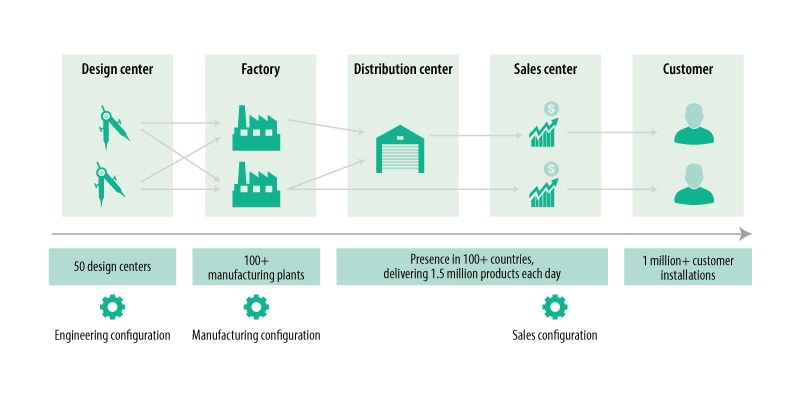

Figure 1. The scale and complexity of ABB’s Electrification business supply chain

Source: ABB

Configuration complexity: legacy inefficiencies

ABB manufactures products for electrification at all points from power generation to distribution and protection. The Electrification business’ annual revenue was $13 billion in 2018. ABB holds the second position in a global market estimated to be USD 160 billion.

Traditionally, the business follows a configure-to-order cycle. Each product is configured and made according to specific customer needs. Speed is crucial in this industry to clearly understand customer requirements and respond quickly. It is a high volume business involving delivery of 1.5 million products each day. Time-to-market for new product introduction is a critical differentiating factor against competitors.

But the Electrification business faced several challenges. Product managers across more than 50 engineering and 100 manufacturing locations did not have one single source of information for products and parts. Each country had its own enterprise resource planning system. Localized tools and processes were not capable enough to efficiently cater to the ever increasing business needs.

Figure 1 shows the complexity and scale of ABB’s Electrification business. The process begins with product design and the creation of a master configuration. Product specifications are then sent to the factories for manufacture, before being distributed to the sales centers where packaging and training manuals are added before final shipping.

As demand changes, or as product design improves, the configuration of the product and its associated components and documents have to change as well. The company did use a standardized configurator tool to manage this complex and detailed process. However, there was a lot of duplication in product data and configuration rules, resulting in inefficiencies, errors and high operating costs.

Configuration changes were further complicated by the following challenges:

- Lack of standard techno-functional language for product managers to communicate with each other. The terminologies differed across locations, applications and processes.

- Compartmentalized product development stages, with the work flow moving from one department to another linearly.

- Variation in manufacturing capabilities which required different configurations for the same product depending at which site it was manufactured.

The legacy configurator and process challenges led to situations where incorrect configurations that could not be manufactured at a particular location were also created. The time-to-market for new products was as high as six months in some instances. This situation was detrimental in a competitive environment with fast moving products and a shrinking shelf life.

The need for digital transformation

ABB’s Electrification business required a transformation and a new system in which all functions and locations used the same data to work seamlessly, transferring accurate data on time. The two overarching objectives were: to establish a single source of the truth, and to enable an “outside-in” approach to product design:

Establishing the single source of truth: This involved creating a single repository of data and terminologies, as well as a single process that all product managers could use globally. It reduces mismatches, miscommunications, and errors. It enables all involved to have transparency of product details and process covering cost, bill-of-materials and manufacturing process details.

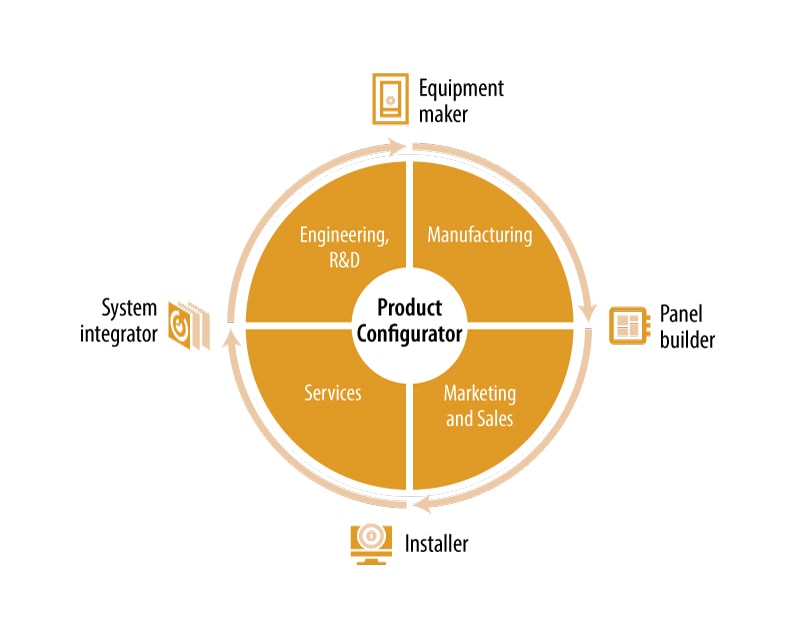

Figure 2. The product life cycle post-digital transformation

Source: ABB

Outside-in approach: Historically, the new product introduction process started from the engineering and manufacturing teams, with very little customer interaction. By the time a new product was conceptualized, designed, piloted and manufactured, it risked not meeting customer needs or becoming obsolete due to competing products in the market. An outside-in perspective originates with the customer’s involvement with the sales team. It involves designing and configuring products based on customer need, and delivering it in time to meet their expectations.

Figure 2 shows how ABB was looking to move from it’s previous linear configuration process, to one that is collaborative and holistic, giving the product manager oversight of, and ability to engage in, each stage of the process. It also enables a feedback loop to be created from each part of the process to ensure that timely corrective actions are taken.

Piloting an e-Configurator

ABB embarked on a pilot implementation of its e-Configure Configurator solution, based on Configit technology. Configit is a leading solution provider for configure-price-quote and configuration life cycle management solutions. The solution is an online, web-based application. It was conceptualized based on a model-and-quote solution and implemented by Infosys.

The project team created a pilot solution to implement the ‘single source of truth’ across a set of 50 users in three countries for one product. The main principles followed in the e-Configurator implementation were:

- Reuse of products and their data such as price, configuration rules and availability information. This ensured that proven parts were used for customer orders instead of creating them each time.

- Global data repositories and rule engines were one source of data for all locations to avoid any duplication.

- Automated data extraction and syndicated processes synchronized data across locations in a near real-time process.

- Solutions were applied only in an online mode to ensure that no data went out of sync with the rest of the enterprise.

The e-Configure configurator has become the unified mechanism for the exchange of product development data. It provides transparency across departments from design and development status updates to manufacturing site conditions. Processes for system design and product catalogs are harmonized across business units and locations. Use cases such as online price lists, quotations and order capture are part of this process. After a successful pilot, the configurator implementation was scaled up gradually to multiple product models across different business units spanning across geographies.

Business impact

The implementation of the new product configuration process and tool simplified the product manager’s job. The cycle time from configuration design to manufacturing came down from 6 months to a few weeks. Collaboration improved up to 45% between Research and Development and sales teams across businesses. Paper catalogs and pricelists were replaced with one central digital repository.

The closed-loop configuration management process ensured zero errors across the process. The team is now able to support the configuration of complex products and adapt to new customer needs easily. Clearly defined metrics are used to measure the entire process health and to ensure transparency. Product managers across different countries are able to talk in the same techno-functional language now.

The new product configuration process and tool improved the collaboration between R&D and sales teams up to 45%

The path forward

The success of the pilot has led to ABB’s Electrification business deciding to replicate the transformation across all its locations. But it is important to understand that this is not just about a technology implementation. The e-Configure solution will not only completely transform business processes, but it will also shift the cultural focus of the organization. ABB’s Electrification business will now be much more customer-led, and quicker to respond to changes in market conditions.

For this roll-out to be a success, a new work culture needs to be developed and supported alongside the implementation of the e-Configure tool. Change management is an important component to ensure that employees understand the rationale behind the transformation and adapt the new way of working effectively