The digital transformation journey

Automotive companies have been industrial revolution pioneers. The internal combustion engine permanently changed transportation, while the moving assembly line transformed manufacturing. And car companies embraced automation when they introduced prototype assembly line robots in the 1960s.

But legacy companies now face a new revolution as digital natives change how vehicles operate, upend established sales networks and radically change consumer expectations.

How automotive incumbents react now will determine what kind of future — if any — they will enjoy. The next generation of pioneers is racing toward Industry 4.0; those who aren’t risk being left behind.

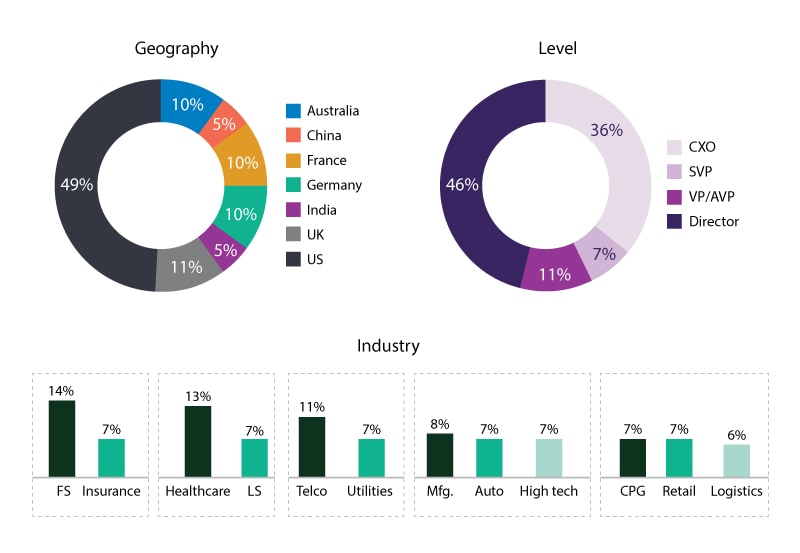

In early 2018, Infosys surveyed more than 1,000 senior management-level executives working in large organizations around the world, defined as those with more than 5,000 employees and over $1 billion in annual revenue. That research on digital evolution included responses from dozens of automotive industry executives.

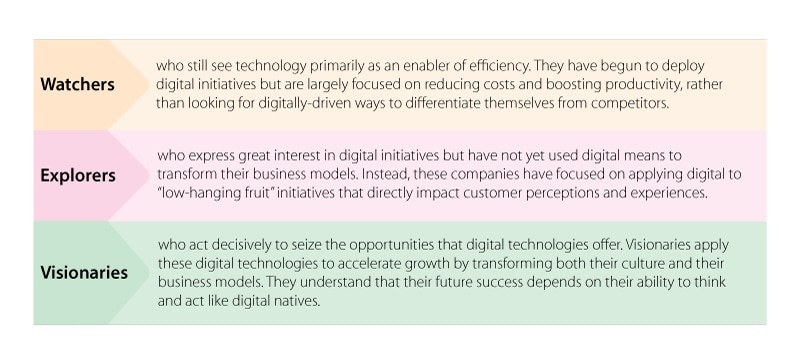

Based on that survey, we produced a report — The New Champions of Digital Disruption: Incumbent Organizations — showing that incumbent organizations (as opposed to digital natives) fall into three clusters determined by their progress along the digital transformation journey:

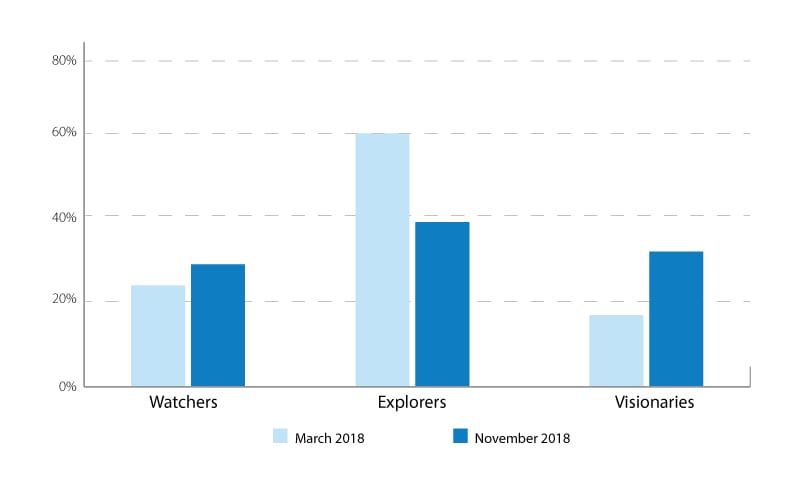

Knowing that many organizations are rapidly intensifying their digital transformation efforts, Infosys conducted a new survey in November 2018 to gauge the pace of that change. The automotive industry shows greater progress than the overall pool of respondents. A large percentage of auto companies moved from the explorer category to the visionary category. In contrast, the survey generally found that it was easier to jump to the explorer level, but that reaching visionary status was significantly more difficult.

This transition is even more critical as major tech companies start to redefine the automotive industry. Auto companies have already led several industrial revolutions and now must now catch up with the newest one.

Fewer explorers, more visionaries

The need to be visionaries

Almost every incumbent automotive company is being pushed by disruptors or peers to digitally transform as connected, autonomous, shared and electric become the new mandate. Many companies will survive only if they become digital transformation visionaries.

Some incumbents, unable to keep up with the pace of technological change, have already succumbed to competitive pressures. Many more in the auto industry will likely fall by the wayside.

To avoid being blindsided by competitors and to stay relevant, companies must find ways to transform their products, processes and business models using digitally-enabled approaches and technologies.

Navigating the transformation journey

Our most recent study takes a closer look at the transformation journey. We identified 22 key digital initiatives and asked respondents where their companies stood on implementing each initiative:

- Not started (or in planning).

- Completed multiple proofs of concept.

- Completed pilot projects.

- Operating at scale.

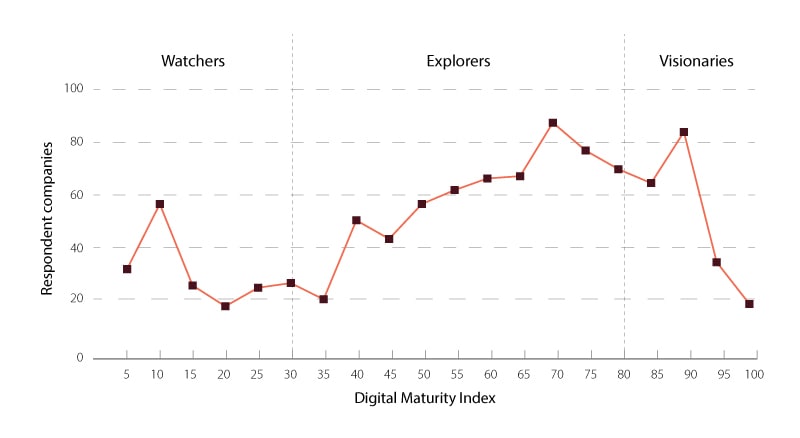

We then developed the Digital Maturity Index and assigned each company an index score from 0 to 100 according to its progress on pursuing and implementing the 22 key initiatives.

Companies on the digital journey

Comparing clusters on their digital transformation journeys

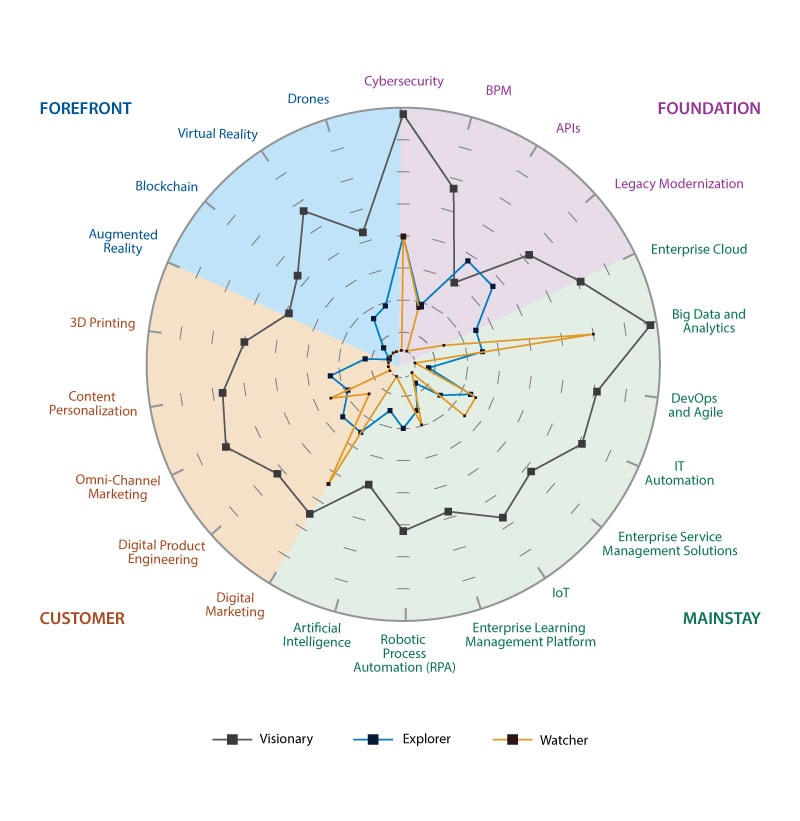

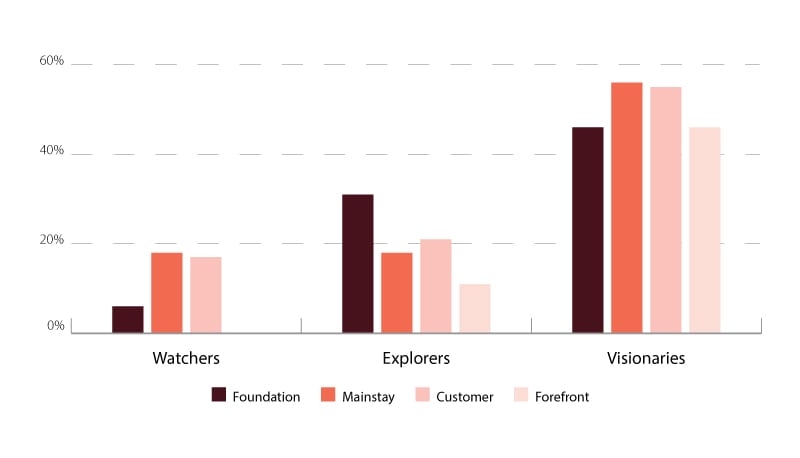

As automotive companies advance through the digital transformation journey from watchers to explorers to visionaries, they operate more and more key digital initiatives at scale. The types of projects change throughout the journey and can be grouped into four categories:

- Foundation initiatives must be implemented to modernize legacy systems.

- Mainstay initiatives represent the core elements of digital transformation, including automation and artificial intelligence (AI).

- Customer initiatives primarily impact the customer experience. They include omnichannel marketing and content personalization.

- Forefront initiatives harness cutting-edge technologies, such as augmented reality (AR), drones and blockchain.

Visionaries stand out – cluster progress across 22 digital initiatives

As shown in the previous figure, automotive visionaries are significantly more advanced than explorers in their implementation of virtually all initiatives, and watchers are far behind.

| Watchers | Explorers | Visionaries |

|---|---|---|

|

|

|

Changing focus, making progress

Visionaries have many more initiatives operating at scale

As automotive companies advance along their digital transformation journeys, they tend to focus on different sorts of projects. Watchers are just trying to build a foundation for their digital transformation, so they are unlikely to have the bandwidth to launch mainstay, customer or forefront initiatives.

As companies reach the explorer stage, they turn their attention to a broader range of initiatives, including such mainstays as RPA, enterprise cloud, and big data and analytics. Massive data growth is expected to come from both manufacturing and connected vehicles, which are predicted to eventually generate dozens of terabytes per day.

Explorers can also spend time working on customer initiatives such as content personalization, digital product engineering and digital marketing. However, they must still invest time focusing on the basics, including scaling the implementation of core foundational initiatives such as legacy modernization, application programming interfaces (APIs) and business process management (BPM).

Automotive visionaries bring many initiatives to scale in the foundation, mainstay and customer categories. They are also the only cluster making substantial progress on scaling forefront initiatives such as 3D printing and blockchain technologies, which offer benefits for the auto industry’s sprawling supply chain network.

Shifting barriers on the digital transformation journey

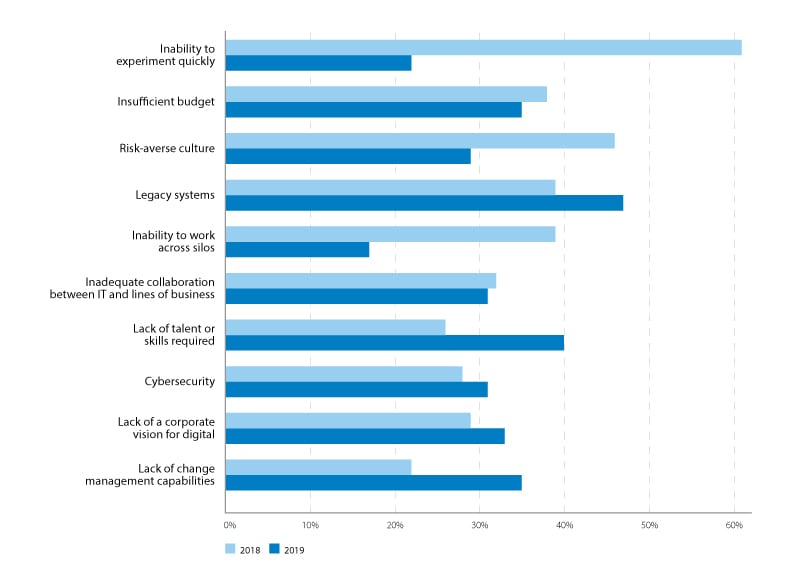

Our survey revealed that an inability to experiment quickly is the greatest barrier to digital transformation that companies faced in 2018. A majority of auto industry respondents (61%) worry that their companies lack the capacity for rapid experimentation that is essential for testing different technologies and figuring out which ones hold the most promise.

Most companies believe that they can quickly develop this capability. Only 22% of respondents felt that lack of rapid experimentation skills would still frustrate their digital transformation in 2019.

Barriers to digital transformation

We believe that companies underestimate the challenge of mastering the art of rapid experimentation. Companies need to implement major cultural changes to become adept at rapid experimentation, according to Alok Uniyal, vice president and head of Agile and DevOps at Infosys. Significant cultural shifts rarely happen quickly.

While automotive industry executives feel that most barriers to digital transformation will diminish over time, they have persistent concerns over legacy systems, such as large, decades-old factories and massive workforces.

Legacy systems currently rank as the third most commonly cited barrier (named by 39% of respondents), but participants expect it to become the most serious barrier in 2019.

Indeed, digital natives cite their lack of legacy systems as a major competitive advantage. “We have no legacy systems, only cloud-based technologies designed not only to meet all our needs now but to be flexible, scalable and adaptable in the future,” noted Yvonne Burkhouse, CIO at HAAH Automotive Holdings – Zotye USA, a startup that seeks to disrupt the car buying process and achieve a new level of dealer and customer service satisfaction. “Our ERP and dealer management system will be combined and built on one unified data platform based on Oracle NetSuite/Advectus. This is disruptive and innovative for dealers as a new way of thinking about one business solution.”

Experience with digital transformation is a double edged sword. On one hand, the visionaries who have progressed the furthest along the digital transformation journey recognize the most barriers, identifying more than four from the list of 10 that we provided.

At the same time, automotive visionaries are also more optimistic about overcoming these barriers than are their counterparts in the watcher and explorer groups. This demonstrates that companies become more confident as they gain experience implementing successful pilots and bringing ideas to scale on their digital transformation journeys.

Survey respondents are also confident that budgetary constraints will become less of a barrier in 2019.

While 38% of auto industry executives cited “insufficient budget” as a barrier to digital transformation in 2018, only 25% feel that it will still be a serious stumbling block this year. If organizations devote more investment to key digital initiatives, it would show that senior leaders are strengthening their commitment to digital transformation.

On the flip side, participants expect that change management will only grow harder as time goes on. While 22% of respondents named “lack of change management capabilities” as a barrier in 2018, 35% said it would be a problem in 2019 for the auto industry. Watchers and explorers are especially worried about managing change.

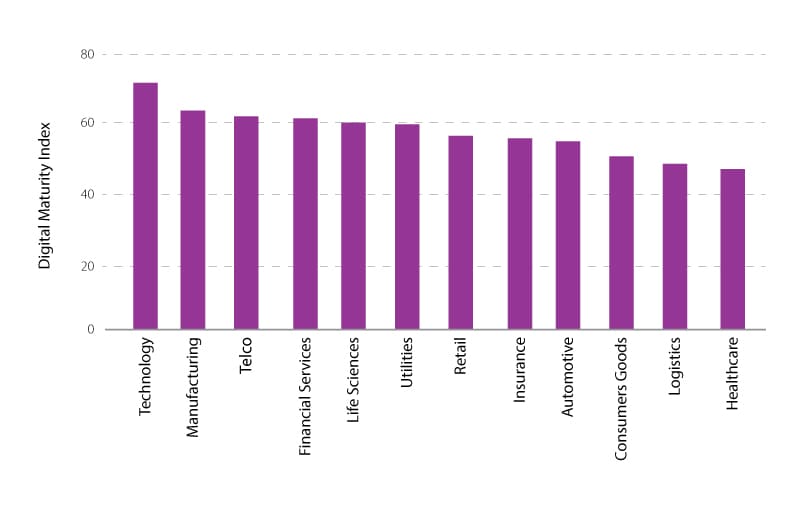

Digital maturity by industry

Our survey revealed significant differences in digital maturity by industry. We found that technology, manufacturing, telco and financial services companies had progressed furthest on their digital transformation journeys. On the flip side, the automotive industry’s Digital Maturity Index score fell in the bottom half.

While players have invested across a broad range of digital investments — with autonomous being the most noteworthy — current challenges include falling sales and margin pressures, which are forcing companies to focus on short-term results rather than transformation. In some cases, individual companies are stalling or even regressing on their digital journeys, according to Randall Urban, a vice president in the Digital Office at Michigan-based parts manufacturer Adient.

Industry ranking on the Digital Maturity Index

Accelerating the digital transformation journey: 5 key capabilities

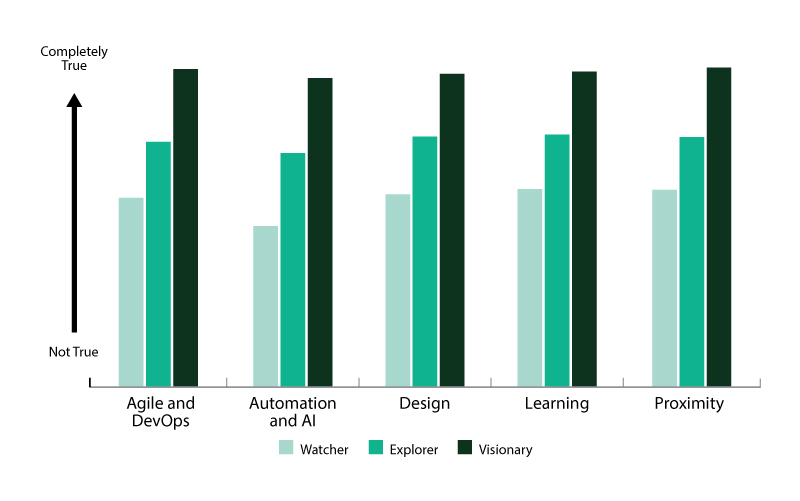

In August 2018, Infosys conducted a research study that identified five capabilities which help companies, including automotive industry incumbents, accelerate their digital transformation journeys: Agile and DevOps, automation and AI, design, learning, and proximity.

In our November 2018 executive survey, we looked deeper to understand company competencies in these areas. We found that companies with the highest Digital Maturity Index scores (i.e., the visionaries) do indeed have the strongest abilities in all accelerator categories.

Visionary companies have superior accelerator capabilities

Cluster average

Each of the five digital capability accelerators above is each powerful in its own right, and we examine each of them on the pages that follow. Before looking at the accelerators individually, it is worth reviewing them holistically at a summary level. When we reviewed client and industry digital transformation programs, we found multiple successes in the past two years where one of the accelerators was dominant.

However, in discussions with executives about the next 12 months and beyond, the consistent message was that multiple accelerators will increasingly be needed for future success. Agile and DevOps programs will be required for the uncertainty that accompanies the frenetic pace of change. The amplification and intelligence from automation and AI will be required to make sense of an increasingly complex world.

Design will become a non-negotiable expectation that goes beyond functionality to experience, and will permeate more and more business functions.

The rate of change faced by enterprises, and the necessity for widespread adoption, virtually guarantee that learning will be a core part of any lasting transformation. Finally, the location or proximity of work will be a major factor in capability and program planning, both for strategic intent and for cost management.

Let’s examine each of these digital capability accelerators.

Digital transformation accelerator No. 1: Agile and DevOps

“There’s an overarching need for companies to be nimble and responsive, to understand company needs, and quickly develop solutions,” said Uniyal, the Infosys Agile leader.

“Agile and DevOps enable companies to beat competitors by quickly experimenting, validating ideas and scaling leading-edge solutions. They enable greater flexibility and higher productivity. DevOps helps by automating the Agile software development lifecycle, enabling companies to deploy new features on a nearly continuous basis.”

These familiar tech strategies are increasingly important for the fast-evolving automotive industry. The lines of code embedded in vehicles are escalating as internet of things, autonomous features and over-the-air (OTA) updates become commonplace.

And this is not just crucial to updating maps or in-car entertainment systems. Tesla has pioneered the use of OTA updates for everything from critical safety fixes to the addition of new features. Other U.S. carmakers have announced they will start using this technology next year.

The visionary automotive companies that are furthest along the digital transformation journey have the strongest ability to deliver Agile programs at scale. They have fully adopted both an agile mindset and Agile practices. Their IT developers and operations teams cooperate closely to achieve business objectives. Their technology teams deliver results fast enough for these legacy companies to stay competitive and fend off digital native rivals. Such visionaries are also likely to have a robust, stable DevOps platform that serves their entire enterprise.

There are two primary barriers that prevent the automotive industry from making more progress on Agile and DevOps.

One major organizational challenge is changing the culture to ensure that business cooperates with IT from the start.

Our research has found that about 80% of development projects are IT-led and IT-sponsored, without early involvement of business stakeholders.

If companies can change their culture and mindset to ensure early business and IT collaboration, they will dramatically increase the likelihood of Agile and DevOps success.

In addition to cultural change, automotive companies need to make sure that their employees are trained in new ways of working. This retraining must extend throughout the organization so that all stakeholders have a good understanding of these new ways of working.

While our survey shows that many companies are confident — perhaps overconfident — in their ability to master rapid experimentation, the reality is that Agile and DevOps techniques are hard to master. Even companies that purport to have flexible, Agile teams may still rely on the same old structured, rigid waterfall development methods inside those teams.

There are practical steps that automotive companies can take to improve their Agile and DevOps skills. Companies can work faster and scale quicker while meeting the demands of global markets by implementing Agile on a distributed basis.

“Companies need to become more dynamic and nimbler,” Uniyal said. “To react faster to changing markets and come up with improved products and services, companies need to have a culture of rapid experimentation, quick development, prototyping and validation. To accomplish this, they need to be able to visualize their end-to-end value chain. This is a major challenge in legacy organizations where the value chain may be fragmented. The best way to overcome this issue is by implementing Lean.”

Digital transformation accelerator No. 2: automation and AI

AI and automation have the potential to radically transform existing business models and unlock new opportunities in the automotive industry, particularly with autonomous and shared mobility.

What distinguishes visionaries from their peers when it comes to AI and automation? Our survey found that visionaries are more likely to have developed and started to implement well-articulated strategies and initiatives for AI, RPA and IT automation. They also tend to approach automation and AI as ways to amplify human capabilities rather than just reduce headcount and costs. Their employees have the skills to implement automation and AI technologies in ways that advance corporate strategic goals.

That said, automotive companies at all stages of their digital transformation journeys are grappling with the ethical implications and opacity of artificial intelligence.

“We need a paradigm shift in how we interact with AI and automation,” said John Gikopoulos, global head of AI and automation at Infosys. “We should apply ethics and control at the personal level, rather than expecting a process, a machine or laws to govern these technologies once they are out in the world.”

Ethics are particularly a concern with autonomous driving, where algorithms must sometimes make life-or-death decisions. And there isn’t always a consensus on the ethical foundations underpinning those decisions. Machine ethics research published in the journal Nature found that moral principles that influence autonomous vehicle actions vary by country.

Better tools are constantly coming to market that give automotive companies new ways to create AI applications. Companies need to figure out the best ways to harness these tools to develop useful solutions that meet client needs.

To maximize the benefits of automation and AI, most incumbent companies will need to convince their own workforce about the benefits of these technologies and reskill employees to make sure that people and machines can work seamlessly together to achieve superior results.

Robots have taken over many assembly line jobs, including painting and welding. But legacy manufacturers have found that a human touch and visual inspection are still irreplaceable on much of the work.

Digital transformation accelerator No. 3: design

Design skills enable companies to rethink every aspect of their business, from internal operations to external customer service. Automotive companies with superior design skills use technology to find novel solutions to serve human needs.

Our survey shows that companies with design strengths are better able to seize opportunities to improve both customer and employee experiences. They are more likely to deploy technology in the form of digital product engineering, content personalization and augmented reality.

Automotive visionaries understand that design is more than mere user experience. Instead of segregating user design within its own silo, they make sure that more people, in more functions across the company, have responsibility to design products and services that maximize user satisfaction.

Design-led companies have effective processes in place to continuously listen to customers. They are committed to testing ideas and iterating them to improve over time. They measure design performance and results with the same rigor that they apply to tracking revenues and costs.

In the automotive industry, Volvo has combined technology and design to create a superior experience for its customers and distinguish itself from competitors. The company built an app called On Call that offers Volvo owners the ability to interface with their cars from a phone or smartwatch — starting the car and adjusting the temperature remotely. But Volvo went much further by partnering with Amazon to let customers accept deliveries right into the trunks of their Volvos. And Volvo XC40 owners can even use the app to give friends and family keyless access to their vehicles and let them borrow their cars.

When it comes to pursuing design-led solutions, Infosys design executive Corey Glickman warned against excessive prototyping. He said too many companies spend millions of dollars a year on prototypes and proofs of concept without ever moving on to implement those pilots at scale. In times of disruptive change, companies must bite the bullet and make big bets. It sometimes takes an industry leader or innovative upstart to establish a new norm. “No one would have a digital twin today if GE hadn’t sunk millions of dollars into developing theirs,” Glickman pointed out.

Systems engineering has emerged as a critical role in the digital age. The best systems designers are diligent scientists with master’s degrees and many years of work experience. This type of talent is in short supply, exacerbating the war for talent. However, the good news is that a systems designer with experience in one area can typically apply his or her knowledge to other domains. “Systems designers understand how large, complex systems behave,” Glickman said.

“As a discipline, systems design is universal enough that someone with experience in financial services can apply their skills and experience to software design or health care.”

On a practical, operational level, our research has confirmed the effectiveness of breaking up large projects into small teams of highly skilled programmers handling the hardest and most important challenges. These all-star coders are hands-on, working iteratively in physical and virtual whiteboard environments, efficiently pulling from reusable code libraries and writing their own fresh code every day. This approach can reduce development time from three months to as little as three weeks. With this arrangement, companies can deliver more effective programming, solve difficult problems faster and reduce technical debt that may have accumulated through legacy programming and processes.

Accelerating innovation is critical in the automotive industry, where new vehicles and features can take many years to develop. Meanwhile, new competitors are taking a tech industry-inspired approach to design and speeding ahead.

Finally, the success of design-led digital transformations depends on the involvement of senior executives.

Digital transformation accelerator No. 4: learning

Companies are facing a significant gap between the digital skill sets they need and the talent available, according to Jonquil Hackenberg, partner at Infosys Consulting. “Recent graduates, even in desirable fields like data science and enterprise architecture, lack the experience and expertise to implement at scale,” warned Hackenberg. “Meanwhile, many legacy IT professionals struggle to engage with subject matter experts in a way that translates business needs to modern, scalable technology solutions.”

Visionary automotive companies are more likely than other firms to bridge this talent gap by investing in the digital tools and infrastructure necessary to support a robust, always-on, continuous learning and reskilling program for employees.

Continuous learning is fundamental to developing the workforce of the future, one that can achieve and sustain digital transformation. Employees must become nimble, responsive and proactive enough to identify and seize the best opportunities made possible by emerging technologies and new business models.

Volkswagen has announced it would retrain 7,000 engineers to work on its ambitious transition to electric vehicles.

Our research findings suggest that such continuous learning programs play an especially important role in helping employees develop skills in Agile and DevOps, areas that are as much mindset shifts as technical skills.

Employees realize the critical importance of continuous learning to keep themselves marketable and relevant in a rapidly changing business world. Beyond internal skills development, learning programs have the added benefit of supporting retention. Employees appreciate when companies make investments in their career development.

Many leading automotive companies have built their own internal training, reskilling and upskilling programs.

Nissan has built a digital university where IT professionals are moving beyond merely delivering technology projects and learning how to partner with the business to identify problems and co-create optimal solutions.

Our research shows that watchers often overlook the substantial benefits of learning accelerators.

For companies looking to make the move from watcher to explorer, investing in learning is an important early step.

Digital transformation accelerator No. 5: proximity

Even though many automotive companies are competing in a global marketplace and have access to a growing suite of collaboration and communication tools, distance still adds complications to any initiative or project. On the other hand, proximity enhances collaboration and can remove physical barriers to success in product and IT development projects.

“Value creation occurs when companies bring teams together end-to-end in proximity,” advised Deverre Lierman, leader of the Infosys Raleigh Technology Hub.

“Companies should deliberately structure their ecosystem and choose their partners with an eye to maximizing innovation, speed and responsiveness. The key is to capitalize on the benefits of high-quality, low-cost locations without sacrificing the advantages that proximity brings. Visionaries balance global delivery centers with nearby innovation hubs.”

These hubs may be internal or involve strategic partners. Our data shows that visionaries are more likely than watchers or explorers to have implemented finely tuned strategies to locate employees together in geographies that balance cost with proximity to partners and customers.

The automotive industry has for years created and nurtured innovation and technology hubs. And the Detroit area now has a collection of tech talent comparable to that of Silicon Valley, as automakers strive to reach their even higher-tech future, according to one think tank report.

Still, even visionaries in the auto industry depend on the contributions and efficiency of distributed development teams. Visionaries supply these teams with effective collaboration tools and implement standards to measure the quality of work these distributed teams deliver. To the extent that visionaries rely on global development centers, they also invest in the infrastructure and systems to minimize the impact of distance.

At the same time, visionaries recognize that there is no substitute for physical proximity, and they are quite willing to establish well-staffed technology and innovation hubs near important partners or customers. That is why Infosys is establishing six new technology and innovation hubs in the United States and staffing them with 10,000 American employees to serve its customers there. Such proximity is especially valuable when working on initiatives involving customer experience, such as product development, content personalization and AR.

Companies looking to reap maximum benefits from proximity should locate their technology and innovation hubs near end users (i.e., clients) and in places that have intrinsic appeal for the talent that the company wishes to recruit and retain.

Locations near top universities are also attractive, since those schools can provide a pipeline of candidates for recruitment and an ecosystem for incubating innovation ideas.

Companies at all stages of digital transformation should strive to create a culture that attracts talent. Our research shows that employees want to work in a collaborative and collegial environment, where they know they can focus on getting results without wasting time fighting turf wars.

Practices and mindset — what sets visionaries apart

Every incumbent automotive company knows that it needs to make progress on its digital journey, but our recent survey indicates most are not moving fast enough.

“We’re driven by the knowledge that the market is changing rapidly,” admits one executive at a leading tier 1 auto supplier. “We want to be ready for all the developments with connected cars, subscription services and multifactor vehicle ownership. But we can’t implement those types of technologies and programs on our current platforms. If we don’t get those capabilities in the next few years, we’re going to lose out to competitors.”

As our survey showed, most legacy companies are still at the watcher or at best the explorer stage of the digital transformation journey. How can they move to the visionary level? What sets visionaries apart from watchers and explorers?

According to our research, visionaries stand out in that they have fully embraced the mindset and practices of both being agile and doing Agile.

To become more like visionaries, automotive companies should put in place a formal digital transformation strategy, and share that plan with employees, customers and partners alike. They should also develop and implement a comprehensive strategy for using automation and AI to bolster human capabilities, rather than just focusing on cutting costs.

These are not trivial matters. Companies will face real challenges around talent recruitment and reskilling, retooling legacy systems, building the five accelerator capabilities, and fighting off lean, hungry digital native disruptors that are making daily headlines in the automotive industry.

The truth is that incumbent companies need to do three things, do them all well, and do them simultaneously:

- Establish the technical foundations for digital transformation.

- Build technological capabilities and talent.

- Innovate at the speed of Agile.

There are two ways that companies can move themselves ahead on the digital transformation path. They can seek to amplify their existing capabilities by focusing on high-value projects with the greatest potential impact, and they can partner with other organizations to gain access to complementary skills and resources.

Amplify

Automotive companies have limited talent resources, so it makes sense to focus systems designers’ efforts on the biggest problems, where the solutions they create will have the greatest impact. “You can amplify the impact of designers by assigning them to small teams where they can work together to deliver scalable solutions that can be replicated throughout the organization,” explained Infosys’ Corey Glickman.

“If you have the right systems and process, a small number of talented individuals can have a big impact on a company’s digital transformation journey.”

The automotive industry needs to figure out which projects to prioritize and how to push the digital envelope where it will matter most. Visionaries are comfortable with different parts of the organization being at different steps in their digital transformation journeys.

Partner

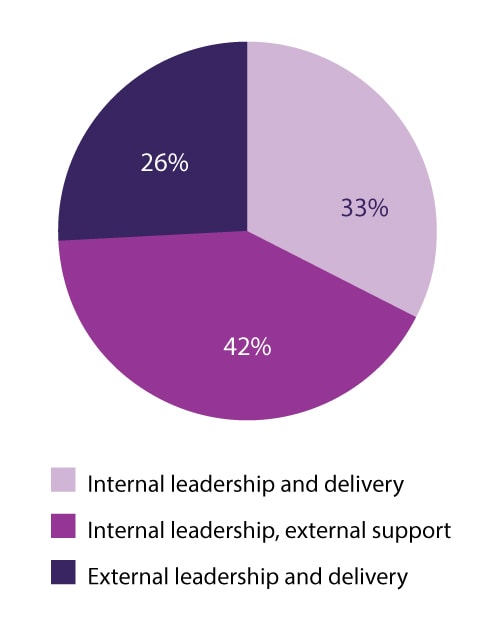

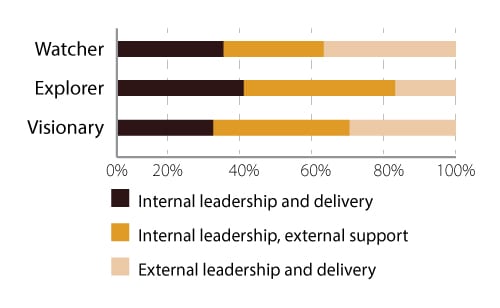

Respondents told us that only about a third of digital initiatives are led and delivered internally; less than half are led internally and delivered by partners, while the remaining one-quarter are fully delegated.

Companies partner for nearly two-thirds of their digital initiatives

There is a significant difference in how clusters handle partnering. In most industries, watchers are the most likely to run initiatives entirely internally, although that’s not true of the automotive industry respondents. Explorers are most likely to lead projects internally while having them executed externally. Overall, visionaries are more likely than the others to let partners run and deliver initiatives on their behalf. In the smaller sample of automotive industry responses, however, the watchers outperformed the visionaries on external leadership and delivery.

Visionaries are more likely to partner on digital initiatives

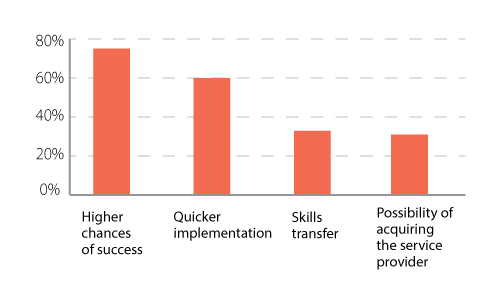

Partnerships have several advantages

According to our research, visionaries are more likely to form partnerships because they have the process and governance maturity needed to build and run them effectively. It’s the same reason companies that invest in architecture and data management are more likely to support API interfaces with external services. Visionaries also have experience building partnerships and understand the multifaceted value of a good partnership, so they are more likely to pursue and forge additional partnerships when opportunities arise.

Visionaries’ digital accomplishments also give them a better appreciation for the unique capabilities that partners bring to the table. When it comes to the vast world of technology, visionaries that develop certain technical skills also tend to learn that they cannot be experts at everything. Instead, they recognize the value of focusing on their core competencies and gaining access to other expertise through mutually beneficial partnerships.

Respondents told us the best partnerships are built on strong personal relationships among humans.

Our survey showed that automotive companies are willing to partner on almost any digital transformation initiative, but they are least likely to work with partners on legacy modernization, where they presumably feel they have the in-house knowledge to upgrade those systems on their own.

Survey participants reported that their automotive companies were most likely to ask an external partner to both lead and deliver on sophisticated initiatives such as drones and VR as well as BPM and enterprise service management solutions. Nearly one third of incumbents in the automotive industry turn to partners for help with these sorts of initiatives that require specialized, hard-to-recruit expertise.

Automotive companies were more apt to favor internal leadership while partnering with external help for execution on initiatives such as enterprise cloud, internet of things and APIs. These areas also require specialized expertise and significant resources, but in-house staff may already have some experience in these fields and thus feel more confident directing such projects themselves.

In the auto industry, incumbent companies have embraced partnerships as a way to better compete with Silicon Valley. Toyota has struck high-profile deals with Uber and NVIDIA for autonomous research and with SoftBank for mobility services.

According to our research, U.S.-based companies tend to view intellectual property (IP) as a proprietary advantage even more than their European and Asian counterparts do. As a result, U.S.-based firms more often prefer to develop high-value innovation in house.

European firms partner for IP in a more transactional manner, while Asian companies have shown more openness for partners to take leading roles in IP creation.

Accelerating the journey

As mentioned in the Amplify section above, every automotive company — including visionaries — needs to prioritize specific digital transformation projects in order to maximize the impact of scarce resources.

How can a company know which projects to prioritize?

- Analyze its level of digital maturity and develop a clear, honest evaluation of current initiatives relative to objectives.

- Assess the short-term future of its industry. What are the key threats from disruptors? Which emerging technologies hold the most promise? How are customer expectations changing? What impact will these factors have on business models?

- Ensure that the company has a solid digital foundation by modernizing legacy systems and working on APIs and BPM. Strength in these areas will enable success in other aspects of a digital transformation plan.

- Strengthen and refine the five accelerator capabilities: Agile and DevOps, automation and AI, design, learning, and proximity.

- Forge relationships with partners whose skills and services could promote faster, better progress toward digital transformation goals.

As with other change initiatives, senior executives in the automotive industry should take an active role in driving digital transformation initiatives.

“You need IT leaders to embrace digital transformation just as much as your digital change advocates,” said a senior auto industry executive. “I’ve seen IT leaders use their power to shut out business partners or minimize the importance of new initiatives around technologies like RPA.”

Automotive industry leaders have to send a signal that such internal power struggles will not be tolerated. Digital transformation journeys can succeed only when individuals from multiple areas of the organization step outside their comfort zones and work across boundaries for the good of the entire enterprise.

The digital future is arriving at a rapid pace, and the consequences of inaction are more severe than ever. Digital disruptors are gaining market share in the automotive industry, and connected, autonomous, shared and electric threaten existing business models.

With proper planning, cooperation and commitment, business leaders, engineers, designers and IT professionals can work together to position their companies for success, no matter which direction the digital winds may blow.

Survey methodology

In November 2018, the Infosys Knowledge Institute used a blind format to conduct an online survey that attracted responses from more than 1,000 CXOs and other senior-level respondents from companies with revenue upward of $1 billion. Respondents represented multiple industries and hailed from Australia, China, France, Germany, India, the U.K. and the U.S.

To gain additional qualitative insights, we also conducted phone interviews with more than a dozen industry practitioners and subject matter experts.

Survey coverage