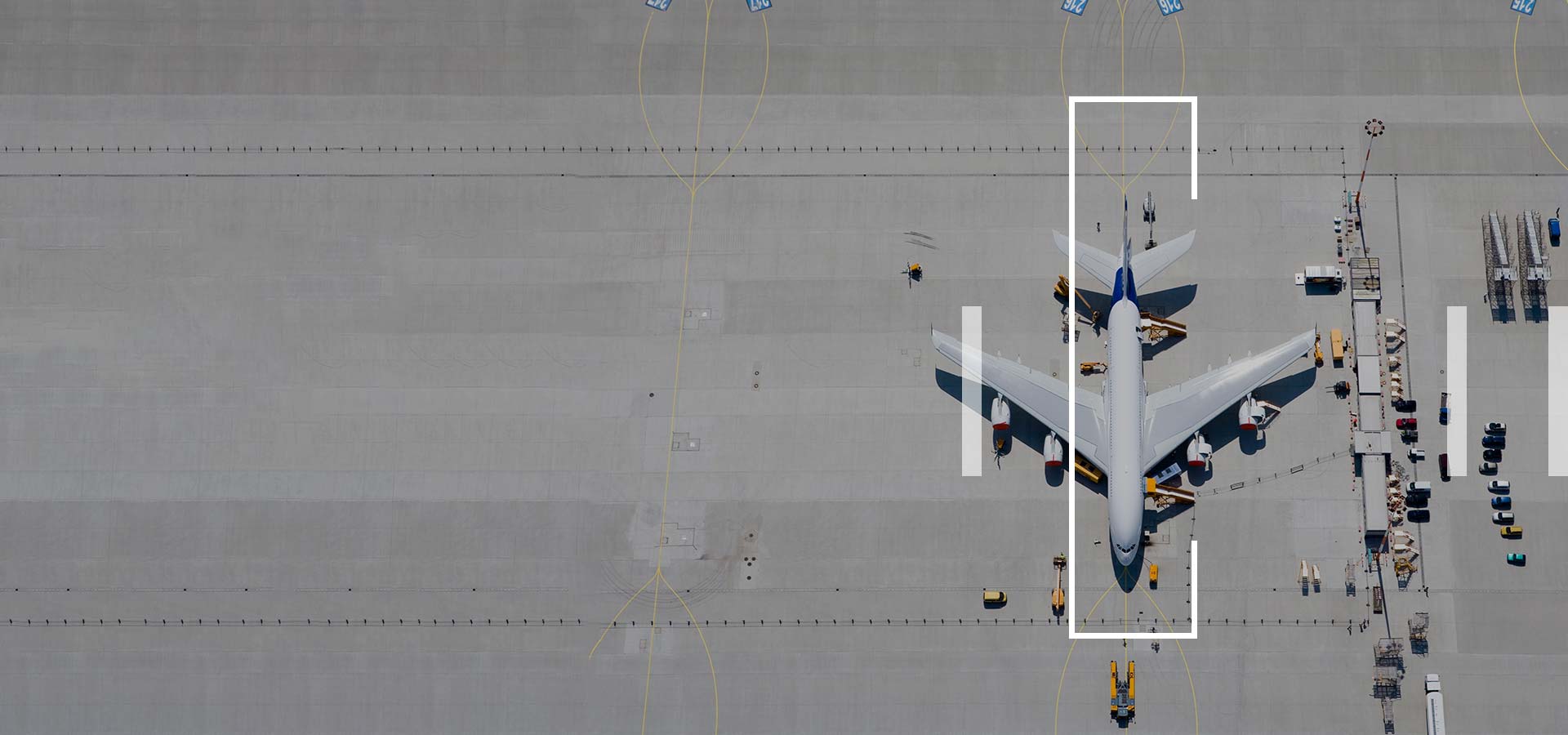

The client designs, manufactures, and services state-of-the-art aircraft engines and auxiliary power systems for civilian and military aircraft.

Key Challenges

Success in aerospace and defense demands operational excellence that combines world-class quality with high velocity manufacturing of aircraft parts and engine components. In addition, the enterprise needs to comply with stringent quality assurance guidelines and industrial safety standards.

The client’s teams across the manufacturing value chain faced several challenges in daily operations:

- Line managers responsible for quality control were challenged by paper-based tracking of production and operations processes.

- Plant management tasked with accelerating production was hampered by lack of visibility into operations.

- Production planners required support to forecast demand reliably due to suboptimal planning and scheduling.

- The maintenance engineering team failed to achieve zero downtime due to production bottlenecks.

- Environmental health and safety (EHS) managers responsible for sustainable operations could not reduce energy consumption and wastage.

Ready to experience?

TALK TO EXPERTS

The Solution

A smart factory underlined by machine connectivity

Infosys undertook a digital transformation of the company’s global manufacturing facilities, connecting machines in factories, offering end-to-end visibility across production, and providing constituents with a macro view of the shop floor.

The Infosys team inspected the client’s workshops and plants to review sensor and wireless capabilities of machinery, and their maturity. We developed a machine connectivity solution and incorporated smart equipment into machines to provide managers with real-time visibility into machine performance.

- Digital thread

Infosys developed a wireless shop floor integration solution, using hybrid network architecture, and installed sensors to monitor the condition of machinery. Our team leveraged data analysis tools to determine overall equipment effectiveness, production availability, performance, and quality monitoring in real time. We embedded smart equipment into machines on the shop floor to provide managers with insights into machine performance. In addition, a proprietary manufacturing execution system monitors production execution, quality and condition monitoring. - Data synchronicity

Our smart factory solution offers managers real-time status with data visualization of process parameters. It allows them to set thresholds and generate alerts based on limits, while accessing historical data for advanced analytics. We implemented a proprietary tool that synchronizes production planning and scheduling. It empowers managers to identify machine, workforce, and material bottlenecks. Importantly, managers can undertake smart scheduling and optimize production by integrating ERP, machine, process, and workforce data. - Smart operations

Our solution enables managers to plan shift capacities and ideal times for each operation, and assign operations to machine groups. It schedules planned downtime for machinery, and allocates operators to a machine based on a human skill matrix. - Sustainability reporting

Our team installed sensors and power meters to track solid and liquid waste, and power consumption to monitor energy use and waste management. We integrated batch management systems to correlate production data for efficient collection and disposal of waste.

A global solution for smart factory operations

Infosys implemented the smart factory solution at three of the company’s maintenance, repair, and overhaul (MRO) facilities in Singapore, connecting more than 100 machines. In the United States, we undertook a digital transformation of eight OEM factories, connecting more than 400 machines.

Our smart factory solution improved operational equipment effectiveness by 20%.

- The new ecosystem increased productivity by 15%, while reducing labor time by 10%.

- We designed and implemented a smart factory process to reduce machine waste by 10%.

- Our solution enabled the company to adhere to aggressive delivery timelines, boosting on-time deliveries by 5%.

Our smart factory ecosystem solution harmonized processes on the shop floor, offered real-time visibility into operations, and accelerated production while reducing turnaround time.

Benefits

Our proactive approach allows early intervention to inspect engines and replace parts while matching demand for spare parts with inventory.

Infosys established a smart factory ecosystem to drive just-in-time manufacturing and optimize production capacity.