Overview

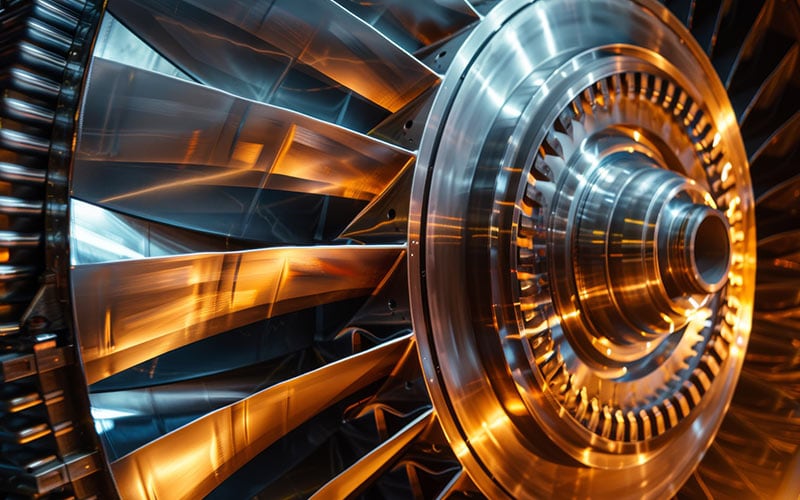

Infosys Turbomachinery and Propulsion services utilize advanced technology to reduce weight, noise, emissions, development cycles and cost while improving fuel efficiency, product lifetime, engine availability and reliability.

Our team consists of over 600 highly experienced domain experts and over 2300 engineers who have successfully designed and developed solutions for major global original equipment manufacturers (OEM), including,

- Gas turbines for power generation

- Aero engines for civil and military aircraft

- Steam turbines for fossil, nuclear, solar, and geothermal applications

- Wind turbines for onshore and offshore applications

- Control systems and plant equipment

We help our clients stay ahead of their competition by leveraging our solutions that deliver on requirements of new designs for performance upgrades, lifetime extension programs and reliability improvements.

Solutions deliver value at speed and scale that helps to optimize cost, enhance efficiency and improve time-to-market

talk to our experts

Our Service Offerings

We offer innovative solutions for global OEMs for their entire product lifecycle, from product development to production and operations.

Gas turbines

- Developing next-generation gas turbines that are fuel efficient, have lower emission levels, and offer higher reliability and availability for end users

- Accelerate time to market by offering a comprehensive suite of solutions across the product lifecycle such as feasibility studies, concept and detailed design engineering, manufacturing support and concession management

Steam turbines

- Market leading engineering solutions which offer highly efficient and flexible turbines, advanced blade profiles and diffusers, long last-stage blade’s covering the entire range of nuclear, combined cycle, industrial, solar and traditional power plants

Wind turbines

- Optimize design for turbine components such as hub and nacelle to reduce cost and improve efficiency

- Carry out root cause analysis (RCA) to identify key pain points and streamline design

Test and validation

- Our integrated engineering and digital package offer one-stop solutions for design testing and validation requirements

- We assist in rig and instrumentation design, data acquisition and test management for performance guarantee, fleet management and automation and simulation

Control systems

- Future-proofing control system solutions in the power domain

- Our domain expertise in basic controls to high end simulations makes us a trusted partner for our customers

Plant integration and accessories

- Offer cost-efficient concurrent engineering solutions for turnkey and EPC partnerships from concept design to commissioning across the spectrum of fossil, combined cycle, solar and hydropower plants

Our Core Engineering Capabilities

Core Engine Skills

Aerodynamics

Heat transfer and cooling

Combustion

Mechanical integrity

Mechanical design

Design for additive manufacture

Control system design

Engine integration

Testing and validation

Plant Engineering and Integration Skills

Piping and arrangement

Construction and commissioning

Mechanical and electrical equipment

System and process engineering

Customer documentation

Configuration management

Key Market Drivers

Business Drivers

- Smart solutions that accelerate time to market

- Higher efficiencies for improved return on investments

- Reduced carbon emissions to meet sustainability goals

- Optimize cost to convert CAPEX to OPEX

Engineering Drivers

- End-to-end design solutions for turnkey partnerships

- Design optimization for better results with reduced cycle time

Innovation Hubs

Infosys Turbomachinery and Propulsion services operate through centers in