Overview

Manufacturing enterprises have typically been hesitant to adopt cloud because the business that requires time critical and reliable human, machine and system interface. However, the need to align to industry 4.0 principles of connected machines, processes, people and ecosystems along with the pandemic’s onset has changed this mindset. Manufacturers are required to collate and analyze real-time data and support data-driven decision-making to transform traditional shop floors into a future-ready smart factory.

Cloud empowers manufacturing enterprises to reimagine a connected future

Manufacturing Cloud is part of Infosys Engineering Cloud and Infosys Cobalt, a comprehensive offering for accelerating the cloud journey for manufacturers in production processes and applications. We have developed a strong ecosystem and capabilities to support different aspects of the Manufacturing Cloud, including simulation, analytics, operational management, maintenance and training. These aspects come with varying complexity - from a single asset to a process unit or an entire industrial plant. The solutions involve multiple advanced and adjacent technologies like data lake, IoT, 5G, edge compute, analytics and AI/ML.

Our Manufacturing Cloud solutions are built on the principles of the digital thread, enabling seamless integration of asset data on a cloud ecosystem, establishing a single source of truth across Engineering, Operational and Information Technologies.

- Engineering Technology (ET) – manages the design and engineering phase, defines, simulates and establishes the digital data for manufacturing, traceability of the material and process compliance. It is detailed as part of Design Cloud

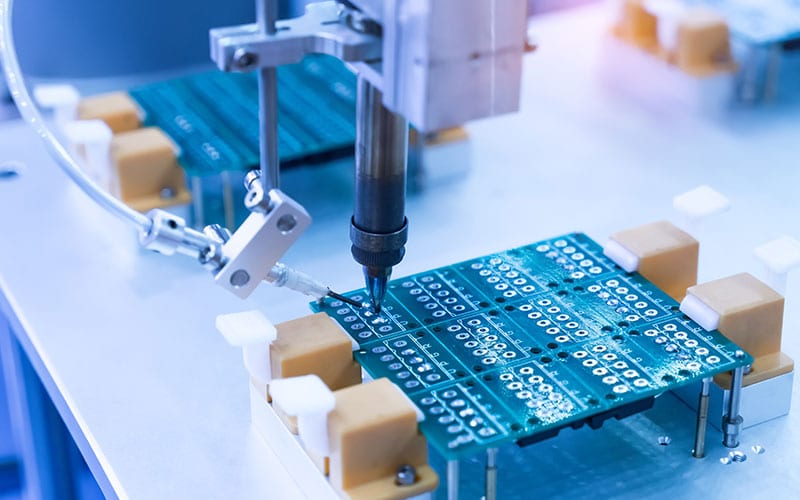

- Operation Technology (OT) – manages product manufacturing, material consumed, the process followed and the quality checkpoints during the manufacturing process.

- Information Technology (IT) – manages the information and data across the horizontal layers of the supplier, manufacturer and end customer and the vertical integration of systems of the manufacturing organization.

How does Manufacturing Cloud enable organizations on their Industry 4.0 journey

Manufacturers require the inherent materials, machines, and processes to collate and analyze real-time data and support data-driven decision-making to transform traditional shop floors into a future-ready smart factory. Manufacturing cloud solutions provide exactly that:

- Navigate remote operations and monitoring at ease

- Respond to changes in real-time

- Facilitate connected processes with higher degrees of automation

- Optimize asset and resource utilization

- Predict the possible impact on operations proactively

A suite of cloud-agnostic pre-configured modular applications connecting machines, processes, systems and people to achieve operational excellence.

talk to our expertsOur Manufacturing cloud offerings are based on the Infosys Live Enterprise Framework guidelines.

- Cloudification: reduce infrastructure, service and maintenance costs

- Rapid: accelerated deployment cycle of 10 - 16 weeks from 10 - 12 months earlier.

- Affordable: lower entry barrier by providing Opex and subscription models.

- Flexible: define customized transformation roadmap to adopt highest value solutions first

- Turnkey: utilize an entire ecosystem of partners, trained talents and innovation via labs

- Sentient: sense, analyze and respond agilely to demanding situations